A Day at Peebles with SafeSmart Aviation

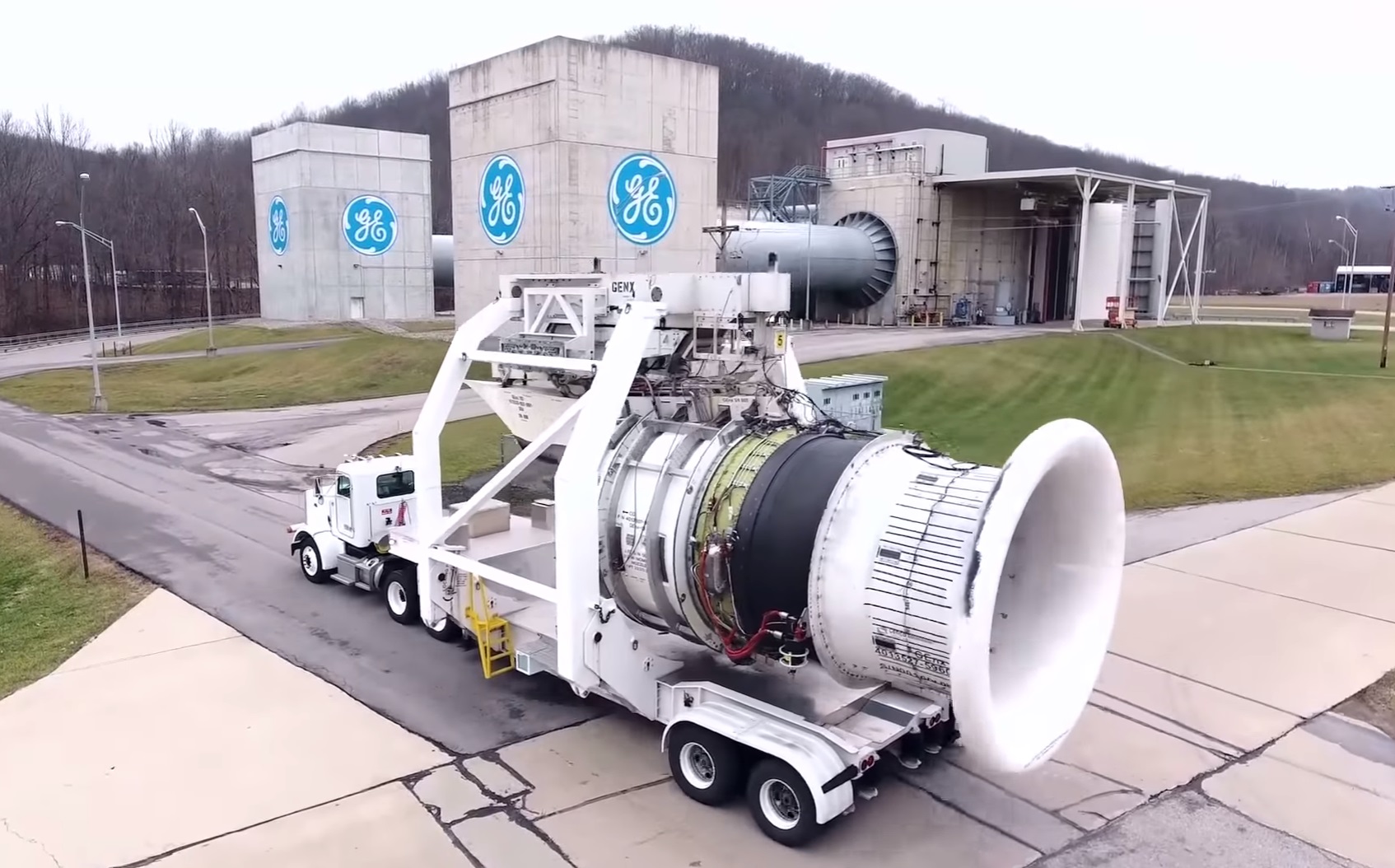

General Electric (GE) have an engine testing facility in Peebles, Ohio, that is famous for a unique structure: a 32 foot-diameter orb. The orb is designed as a ‘turbulence control structure’, which smooths out the flow of air into a jet engine during simulations of engine distress.

In a GE report , Aerospace engineer Jose Gonzalez says the structure makes the test site more efficient, and that it allows him to manage changes in airflow caused by the weather – “You don’t want that as a variable when you collect performance data across many days and under different conditions.”

GE is the largest landholder in Ohio, with several test facilities scattered through 7000 square miles of remote woodlands. The controlled-airflow engine distress test is just one type of study done at the facility – it is the last stop for engines before they are fitted to aircraft, so they are put through ‘groaning trials that involve hail and ice blasts, hurricane-force winds, bird strikes and other extreme hardships’.

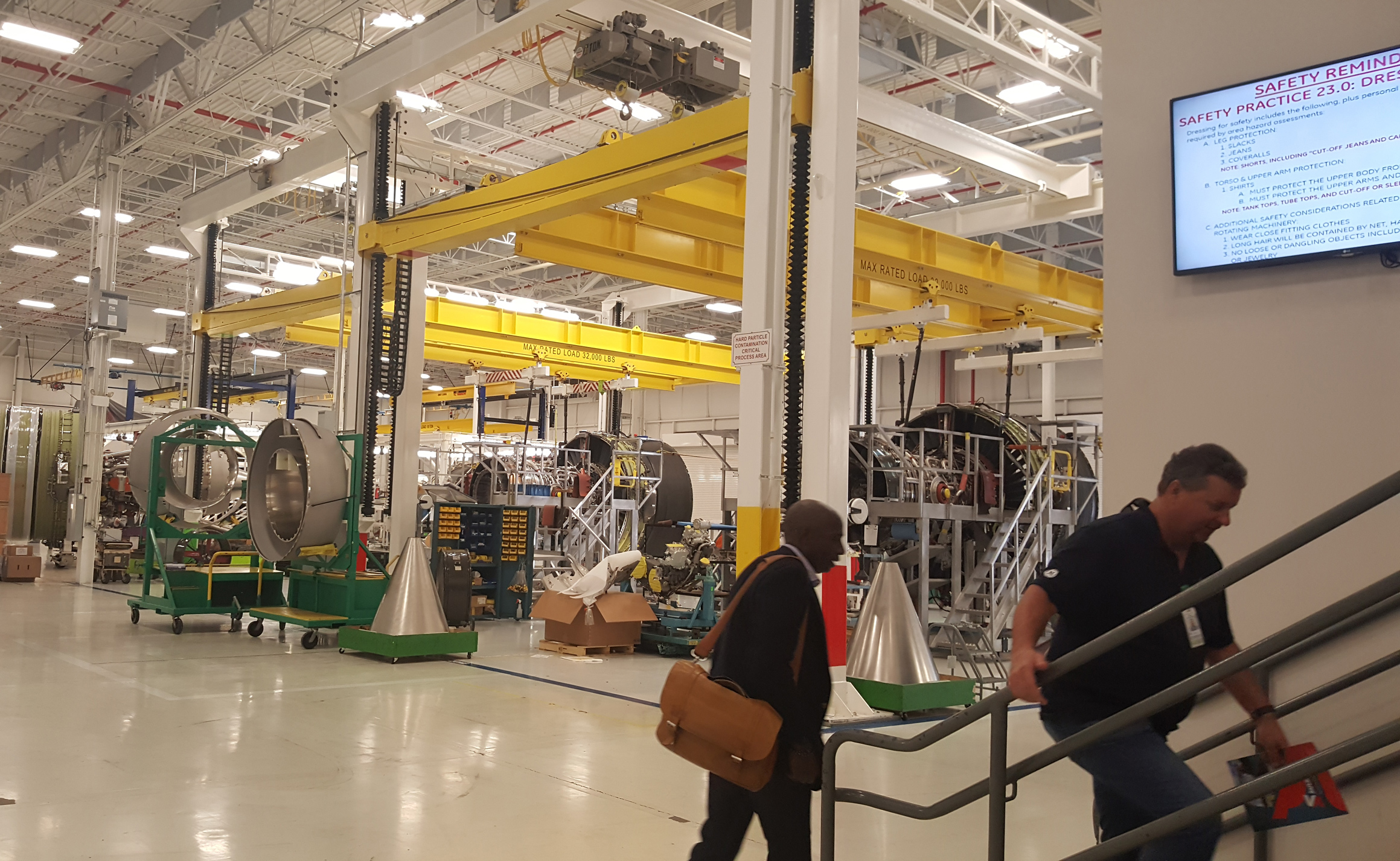

GE recently held a #GEInstawalk tour, inviting six of Instagram’s best photographers into the facility to document it. And this rare moment of open-door-policy to a select few was extended to Ohio portable height access supplier SafeSmart Aviation . SafeSmart’s Shane Wearmouth visited GE in a pre-consultation capacity, and managed to assess the site for opportunities to help the facility operate even more efficiently and safely.

The facility operates 24 hours a day—with few neighbourly few noise complaints, except in the winter, when 24/7 testing noise carries further. And all engines are tested for four hours—so efficiency is key to getting the engines back out on the road to GE’s manufacturer clients.

SafeSmart Aviation specializes in customized maintenance platforms and steps around aircraft and aviation componentry, like in a previous project, where an access system for a United B787 engine during maintenance was designed and installed at LAX. With most workplace accidents and death occurring from falls from height, SafeSmart design and manufacture aircraft maintenance platforms for any aircraft, or for any point of the aircraft – nose, tail, stabilizers, oil check points , refueling points, around engines and up into wheel wells, for example.

As part of GE’s roadmap of new products, the GEnx90 is in production at Peebles, due for deployment within the next two years. With this engine’s 144” diameter, current access platforms will not suit it for maintenance and checks during testing. SafeSmart are currently proposing a specification and assessment on the engine’s needs, and the needs of its technicians, with the view to possibly construct a completely customized system manufactured from marine grade aluminum for a combination of strength and hand-maneuverability.

And throughout the rest of the facility, current aluminum platforms—designed in-house and manufactured by a local general-purpose fabricator—were assessed for compliance and effectiveness. GE are looking to SafeSmart Aviation for new options that will comply, and are better-designed with the needs of the technician in mind – working at height for long period of time, and the need for a weight rating and platform width that would accommodate tools during works.

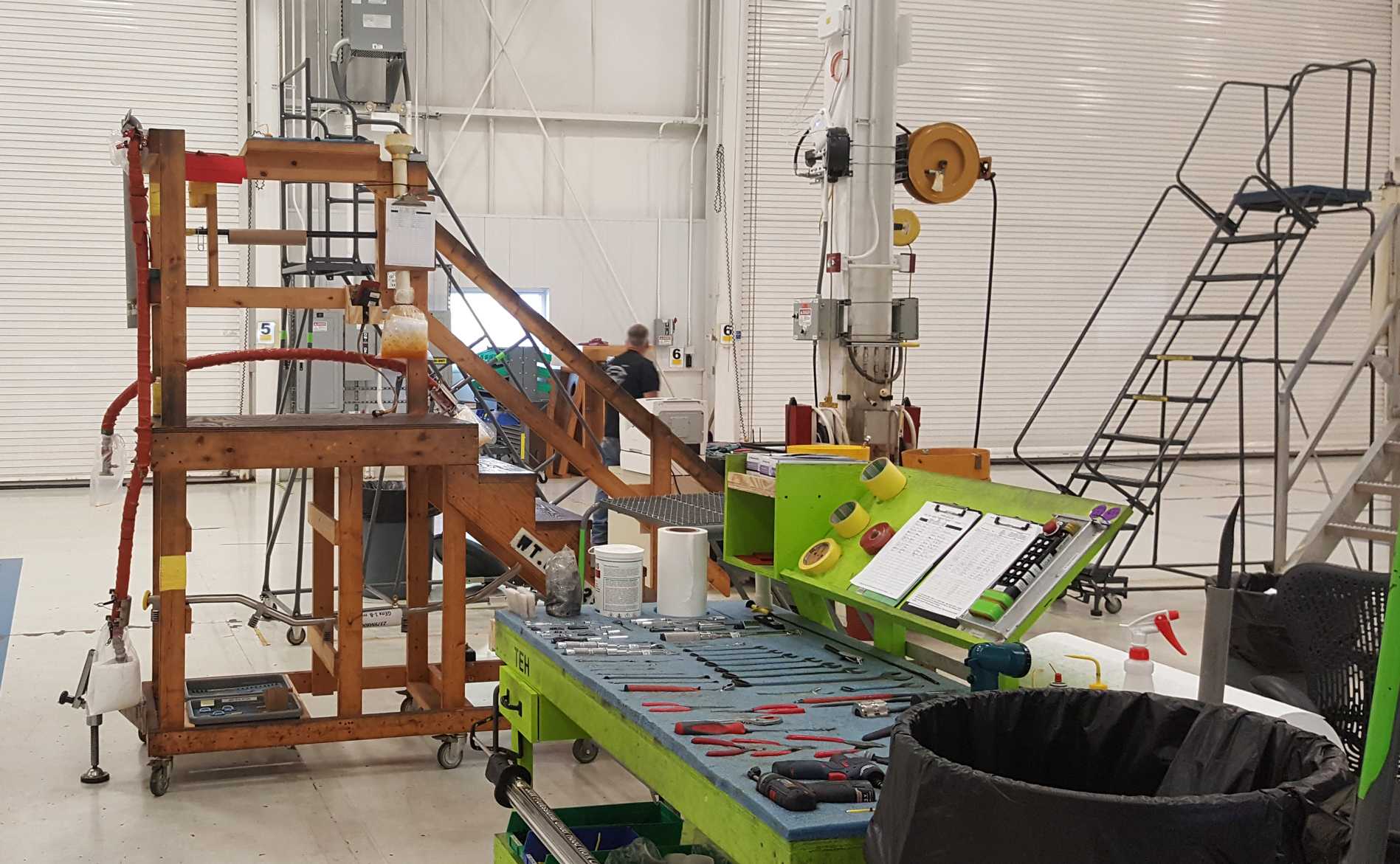

Clockwise from top left: 1. SafeSmart Aviaion representatives walk the GE floor. 2. Fancase inspection. 3. 'The Orb' airflow control chamber. 4. GE's vintage timber height access solution. Still perfectly functional, but a little bit cumbersome and susceptible to ageing.

GE even have wooden platforms in use that are, while relatively safe and compliant for now, destined to be heavily-weathered by Ohio’s extreme seasonal conditions. SafeSmart are also developing proposals for the replacement of those units.

Another new challenge is getting access to the GEnx90’s upper fan case, with a hanging access basket in development by SafeSmart that will attach to gantry cranes.

The development of the GEnx90 and GE90 engines has seen the need to expand the Peebles site, which has been in operation for nearly 62 years. SafeSmart Aviation are looking forward to potentially help GE with this expansion, through close consultation with the way added safety can add efficiency as a result.

SafeSmart Aviation’s USA and Canadian branches are in Los Angeles, New York, Cleveland and Oxbow.