The Specialized Airbus A350 Hydraulic Bay Access Stand

The Airbus A350 Hydraulic Bay Access Stand is a thoroughly engineered maintenance platform. It is an indispensable tool for Maintenance, Repair, and Overhaul (MRO) crews working on the A350 undercarriage. This specialized stand provides safe, efficient, and precise access to the critical hydraulic bay area, which houses vital components for the aircraft’s landing gear and control systems. Maintaining a secure and optimal working environment is paramount, given the importance of these systems to flight safety and operational readiness. This access stand delivers exactly that.

Its primary function is to position technicians securely and comfortably at the exact height and reach required for inspections, troubleshooting, repairs, and fluid servicing within the hydraulic bay. This area is typically complex and difficult to reach from the ground, making a tailored access solution indispensable for maintaining the aircraft’s integrity. The stand’s core purpose is to ensure that foundational maintenance tasks—from checking hydraulic lines and reservoirs to performing functional tests—can be carried out efficiently. This minimizes aircraft downtime and maximizes technician safety.

Durability and Safety Features of the A350 Hydraulic Bay Access Stand

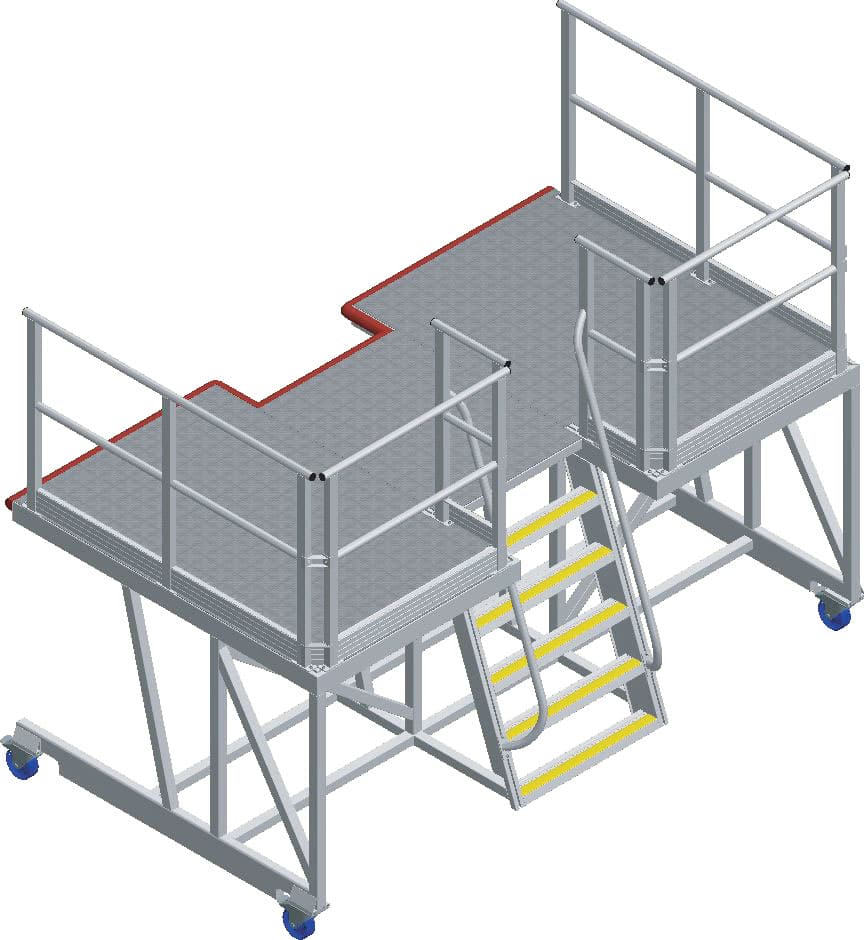

Constructed from high-tensile aluminum, the stand balances hard-wearing durability with manageable weight. This allows for easy repositioning without compromising structural integrity.

Enhanced Traction and Fall Prevention

The working surface features high-grip perforated deck material, providing superior traction even in potentially slippery environments common around hydraulic systems. Further enhancing safety are comprehensive guardrail systems. The stand includes horizontally-sliding telescopic guardrails that lock firmly into place, creating an impenetrable barrier against falls. These protective measures are supplemented by removable or sliding guardrails, offering various configurations to accommodate different maintenance procedures and surrounding structures. This ensures technicians can adapt the platform to specific job requirements while maintaining safety standards.

Mobility and Non-Contact Design

For the deck itself, durable treadplate decking material is utilized, guaranteeing a long service life under heavy use. Removable handrails and steps equipped with grip tread nosing further contribute to secure ascent and descent. Innovative features include its maneuverability. It is equipped with 150mm heavy-duty swivel braked castors. This allows MRO personnel to easily wheel the platform into the precise position required beneath the A350 undercarriage. Once in place, the sturdy braking system locks the stand securely, ensuring stability throughout the maintenance operation.

The A350 Hydraulic Bay Access Stand features a critical cantilevered design. This engineering choice allows the platform to reach non-contact over the aircraft’s wheels and tires. This enables technicians to service crucial oil and cabling points within the hydraulic bay without any risk of damaging the landing gear components or interfering with other adjacent aircraft structures. This non-contact reach is vital for preventing accidental scrapes or pressure points on sensitive components.

Optimal Maintenance Access with the A350 Hydraulic Bay Access Stand

Optimized Utility for Airbus A350 Maintenance

Flexibility in application is a hallmark of this stand’s design. The structure can be mirrored, allowing for configuration for either the left-hand or right-hand undercarriage positions. This dual-use capability eliminates the need for two separate, dedicated stands, providing superior utility and maximizing space efficiency in hangars and maintenance facilities. This specialized platform ensures regulatory compliance and improves the ergonomics of complex tasks.

The stand focuses solely on the intricate and safety-critical hydraulic bay, offering a dedicated, stable, and highly adaptable workspace. It dramatically reduces the reliance on makeshift access methods, directly impacting the quality and speed of maintenance operations. The precision of access facilitated by this stand is crucial for technicians performing detailed inspections, where clear sightlines and stable footing are mandatory.

By focusing on the hydraulic systems—the heart of the aircraft’s movement and control capabilities—this access stand plays a fundamental role in maintaining the airworthiness and operational efficiency of the Airbus A350 fleet globally, supporting the rigorous demands of modern civil aviation MRO protocols. It is a purpose-built solution that integrates seamlessly into the high-precision environment of airframe servicing.