Optimized Access for C-130 Engine Maintenance

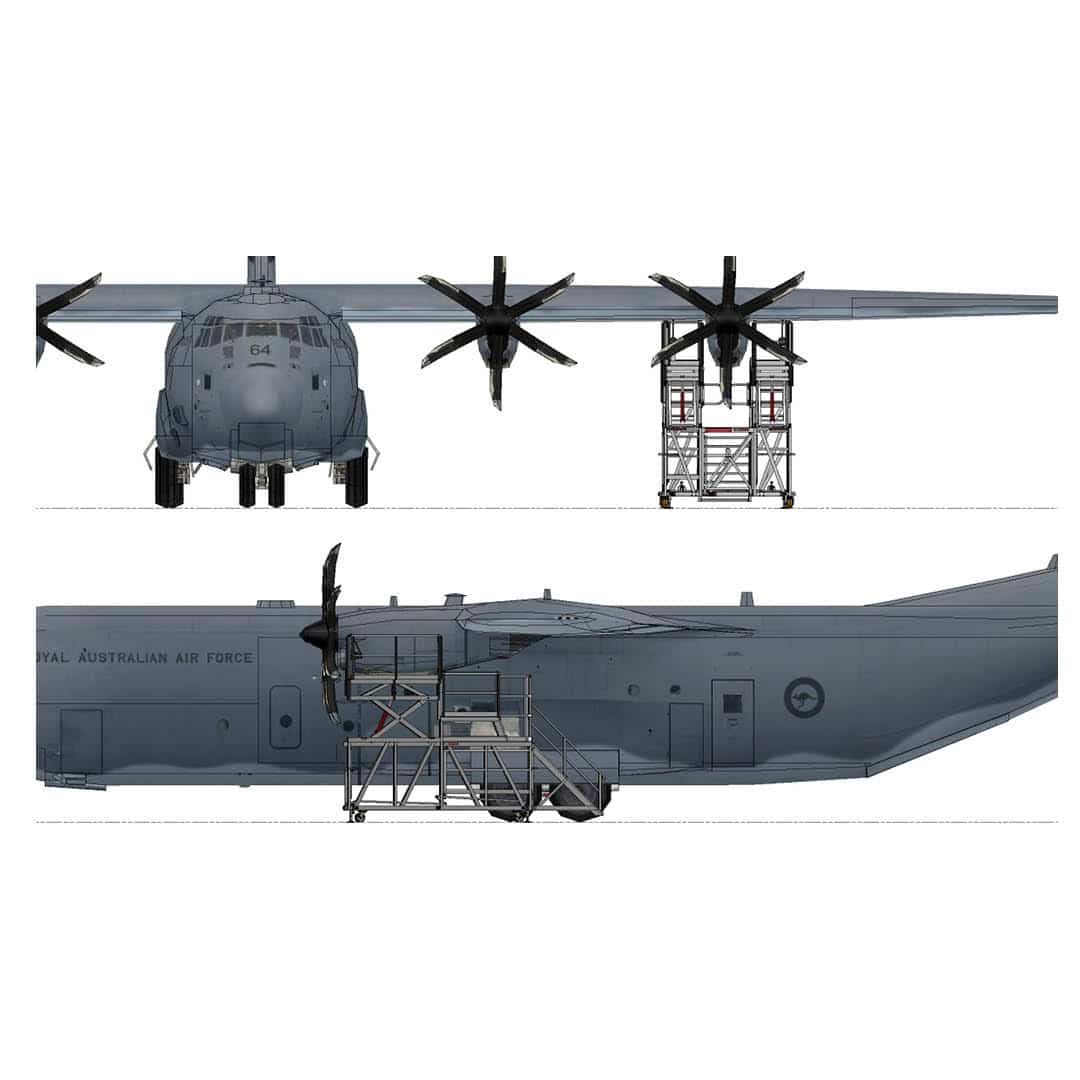

The Lockheed Martin C-130 Engine Body Work Stand is a detailed access solution engineered to enhance maintenance, inspections, and repairs for C-130 Hercules aircraft engines. This sturdy, mobile platform delivers comprehensive, safe, and efficient access for detailed work, including full engine changes and heavier maintenance procedures, focusing on critical access areas for the C-130 Engine Body Work Stand.

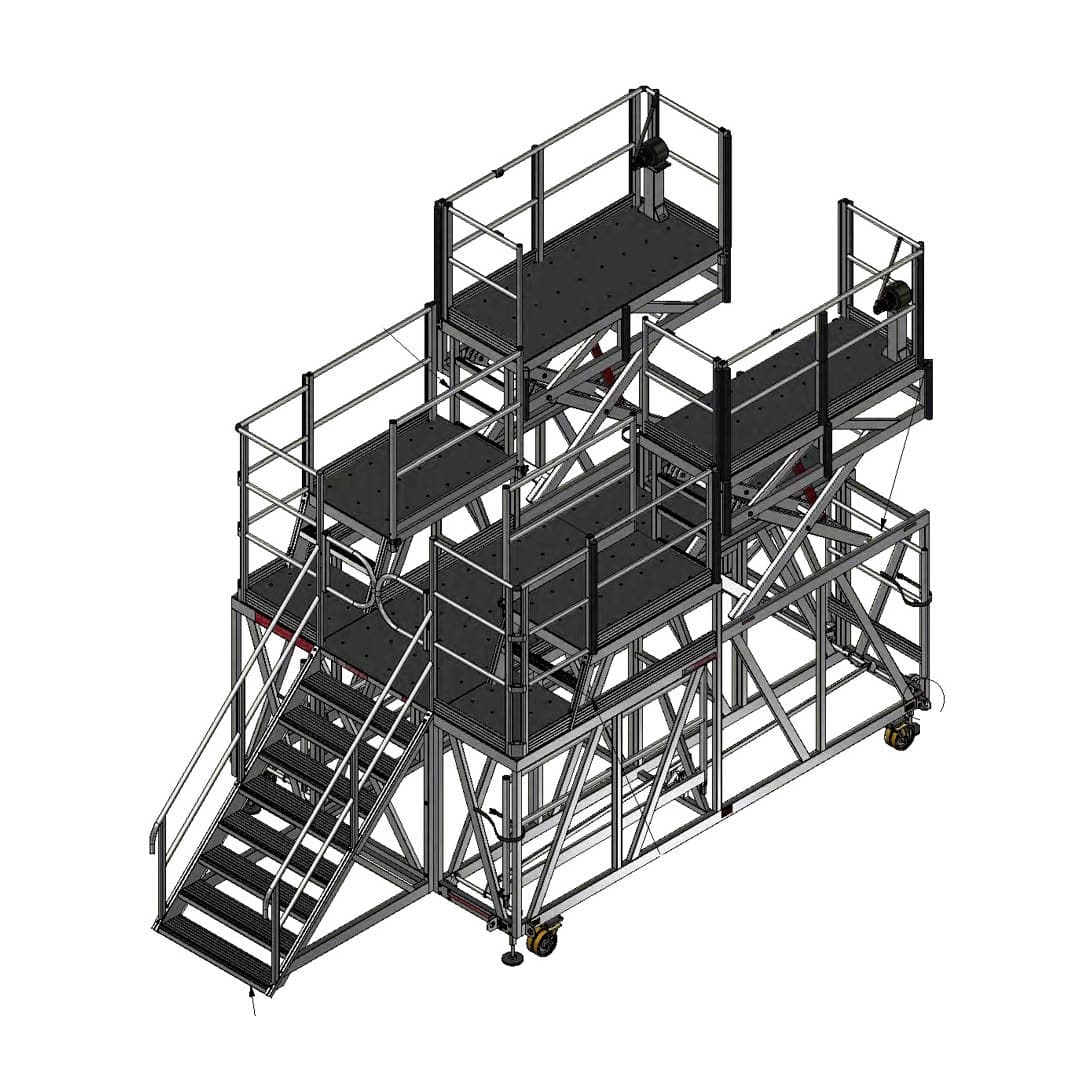

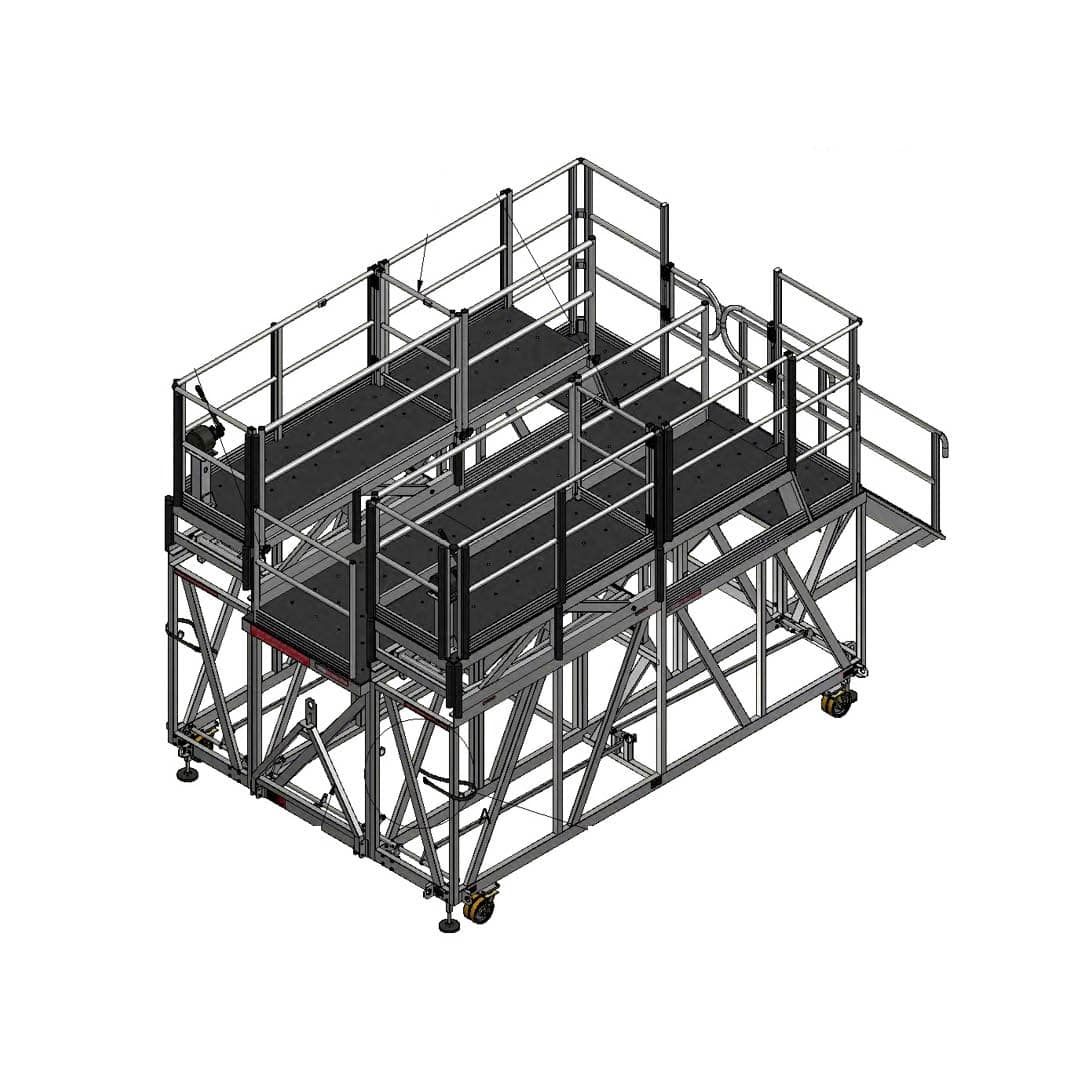

We understand the complex demands of C-130 engine maintenance. This system is purpose-built to solve critical access challenges. It is structured as a 3-PIECE SYSTEM: a Central Unit & Stair, Side Unit #1, and Side Unit #2. This modular design allows for versatile deployment and complete, simultaneous engine access. The design specifically accounts for the varied contours and maintenance areas of the C-130 engine, ensuring technicians reach every foundational point safely and without obstruction.

Precision Height Adjustment for C-130 Engine Access

Innovative features include varying platform heights, which ensure safe and efficient access across different areas of the C-130 Aircraft Engines. Two portions of the platform are height-adjustable, offering an additional 850mm of vertical movement. This critical adjustment capability is managed via a manual hand hydraulic pump conveniently positioned at the top of the stand. Battery-powered variations are also available for enhanced operational flexibility.

This precise height control is vital for aligning with specific engine components during maintenance, facilitating tasks that require intricate positioning.

Safety and Mobility of the C-130 Engine Body Work Stand

Access and mobility are central to the stand’s utility, supporting our commitment to People Safety First. Main access to the platform area is provided by a 45-degree stair, promoting safe and comfortable ascent and descent for personnel, even when carrying tools.

For access to the raised sections and upper adjustment heights, 70-degree access ladders and telescopic vertical ladders are integrated. A self-closing gate at the platform’s access point, along with Lift-out Guardrails and inner removable guardrails, ensures continuous fall protection. These features allow unimpeded access to the engines when necessary.

The guardrail system includes Batwing gates to the top of the stairs, Magnetic Gate Latches, and a Nylon Slide Bolt, all contributing to superior worker safety. Guardrail stowage straps are included for organized storage when the rails are removed or folded.

Durable Construction for Harsh Environments

The platform material itself is optimized for performance and safety. It features perforated and swaged decking with rubber matting overlay, which provides superior grip and allows moisture to pass through flush perforations, maintaining a slip-resistant surface.

Crucially, Foam rubber buffering is present on all sides of the platform where contact with the aircraft is possible, protecting the C-130’s sensitive exterior during platform movement and use. High-visibility reflective tape is affixed around the platform’s circumference for added safety and visibility in dimly lit hangars.

SWL and Modular Capabilities

Mobility is assured by four large 200mm diameter, heavy-duty casters. These are swivel/braking casters, with the pair opposite the tow point featuring directional locking capabilities for precise maneuvering and positioning. The Folding Towbar facilitates movement across the maintenance facility. When the tow hitch is stowed, it automatically engages a lever brake mechanism with four points that prop the stand off the support surface, ensuring complete stability during maintenance operations. Lifting the towbar automatically engages the brakes, adding an immediate safety layer during relocation. This system is designed to be Efficient.

Designed for tough operation, the stand features a Safe Working Load (SWL) of 1000kg. It also includes labeled and rated tiedown lugs for secure deployment. Its modular nature allows it to be broken down into three main modules. This makes it specifically capable of being stowed and deployed within a C-130 transport aircraft, highlighting its expeditionary capability. For comprehensive access solutions, the C-130 Engine Body Work Stand is designed to seamlessly join with the Propeller Stand, creating a complete engine/propeller access system for comprehensive aircraft upkeep.

The overall dimensions of the stand are 4.19m in length, 2.99m in width, and a height ranging from 1.848m to 2.415m–3.265m, depending on the adjustable sections. This platform is suitably sized to grant full engine access for performing complete engine changes, significantly streamlining maintenance workflows and enhancing technician efficiency on the Lockheed Martin C-130.