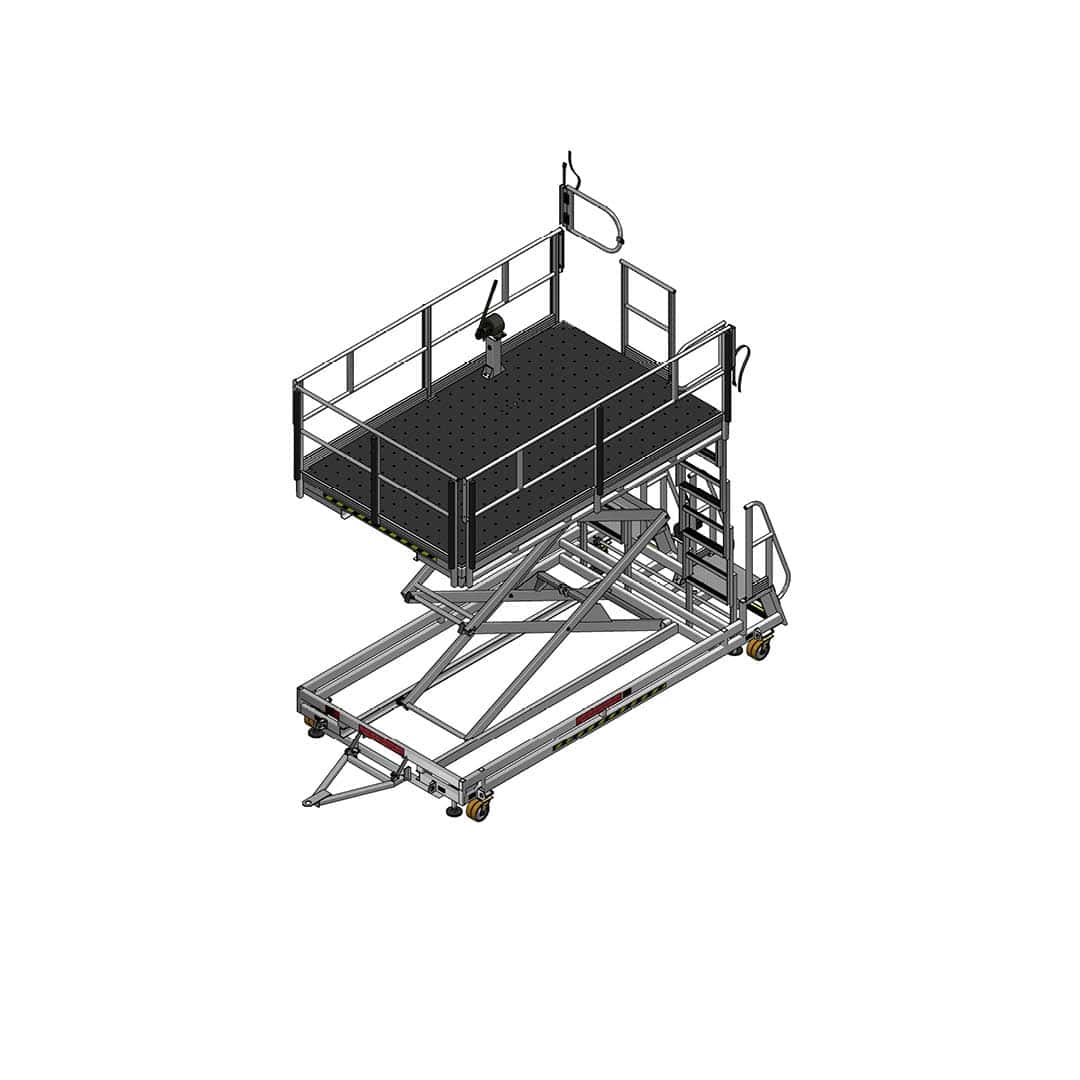

Lockheed Martin C-130 AF-BF Services Work Platform for Hercules Maintenance

The Lockheed Martin C-130 After Flight and Before Flight (AF-BF) Services Work Platform is an indispensable, highly configurable access solution. It is designed to facilitate comprehensive maintenance and inspection tasks on the C-130 Hercules transport aircraft. This platform provides safe, stable, and ergonomic access for personnel to efficiently execute critical pre-flight and post-flight services, maintaining the airworthiness and operational readiness of the C-130 fleet.

Engineered specifically for the C-130 airframe, the C-130 AF-BF Services Work Platform is foundational for technicians conducting detailed visual inspections and hands-on maintenance across low-to-mid-level aircraft areas.

The expansive platform work area and impressive height-adjustable capabilities are key to its versatility. The platform offers a large vertical working range, from a minimum height of 0.75 meters (approximately 2.5 feet) up to a maximum of 3.0 meters (nearly 10 feet). This extensive adjustability is achieved via a sturdy hydraulic system utilizing a scissor arrangement, controlled by a hydraulic hand pump conveniently positioned at both the top and bottom.

Seamless Positioning for Critical Zones

This feature ensures seamless positioning to align with key maintenance zones, such as inspecting landing gear components, checking lower fuselage panels, accessing engine cowlings and nacelles, and conducting checks on control surfaces and wing leading edges when the aircraft is at rest. Battery-powered height adjustment variants are also available for enhanced speed and convenience in the hangar or on the flight line.

Safety Features and FOD Prevention

Safety and efficiency are paramount to the design. The platform incorporates high-strength, durable construction materials and features perforated and swaged decking to allow moisture to pass through. Non-slip rubber matting covers the decking for superior grip and hazard mitigation. All components are retained, a critical design element that prevents Foreign Object Debris (FOD) hazards in the maintenance environment.

Worker protection is maximized by the comprehensive guardrail system. Telescopic guardrail frames are installed on all sides of the platform. These rails slide down to mid-rail and toe-board height, providing full fall protection while remaining adjustable to accommodate specific access requirements during maintenance procedures. Further enhancing safety are removable, self-closing gate panels at the access points, ensuring continuous perimeter protection.

Dual Access and Ladder Options

Access to the platform is provided through dual access points, utilizing a combination of a 70-degree access ladder and vertical telescopic ladder options, offering flexibility depending on hangar space and positioning. The telescopic ladder can also be stowed when not required.

Enhanced Mobility and Stability

Mobility is vital for a busy flight line or maintenance facility. The platform is mobile on large, heavy-duty 200mm diameter casters, allowing it to be easily towed and repositioned by a small team. The casters opposite the tow point swivel and directionally lock, providing precise maneuvering control. Once in the desired maintenance position, a single-lever action four-point braking system secures the platform for exceptional stability.

The towbar is equipped with a rubber buffer to protect the aircraft and platform structure during movement. Lifting the towbar automatically engages the brakes, adding an indispensable layer of passive safety.

Designed for demanding aircraft environments, the platform has a Safe Working Load (SWL) rating of 500 kilograms (approximately 1,100 pounds), supporting multiple technicians, tools, and aircraft parts simultaneously. Innovative features include toolless pins with lanyards for easy configuration, Camloc straps for secure storage, labeled and rated tie-down points, and hi-visibility reflective tape along the platform circumference.

Foam rubber buffering is strategically placed on all sides where contact with the aircraft is possible, protecting the C-130’s fuselage from incidental damage during docking and use. The entire structure is also designed to be stowed and deployed within a C-130 itself, highlighting its expeditionary capability. This comprehensive design ensures maintenance crews safely and efficiently complete all routine AF-BF checks, from general airframe inspection to detailed subsystem servicing.

See our armpit stands for further access.