Specialized AW169 Tail Access Platform for Helicopter Maintenance

Enhance your maintenance efficiency and protect your technicians with the specialized AW169 Tail Access Platform for the Leonardo AW169 light-medium twin-engine helicopter. This advanced work stand is engineered to provide comprehensive, secure access to the critical maintenance zones on the tail section, tail rotor, and horizontal stabilizers of the AW169. This platform’s foundational purpose is simple: eliminate fall risks during routine checks and maintenance on the high, cantilevered components of the aircraft’s tail. It is a leading asset for operators and MRO facilities, enabling technicians to service areas that are otherwise difficult or hazardous to reach efficiently.

Precise Aircraft Integration

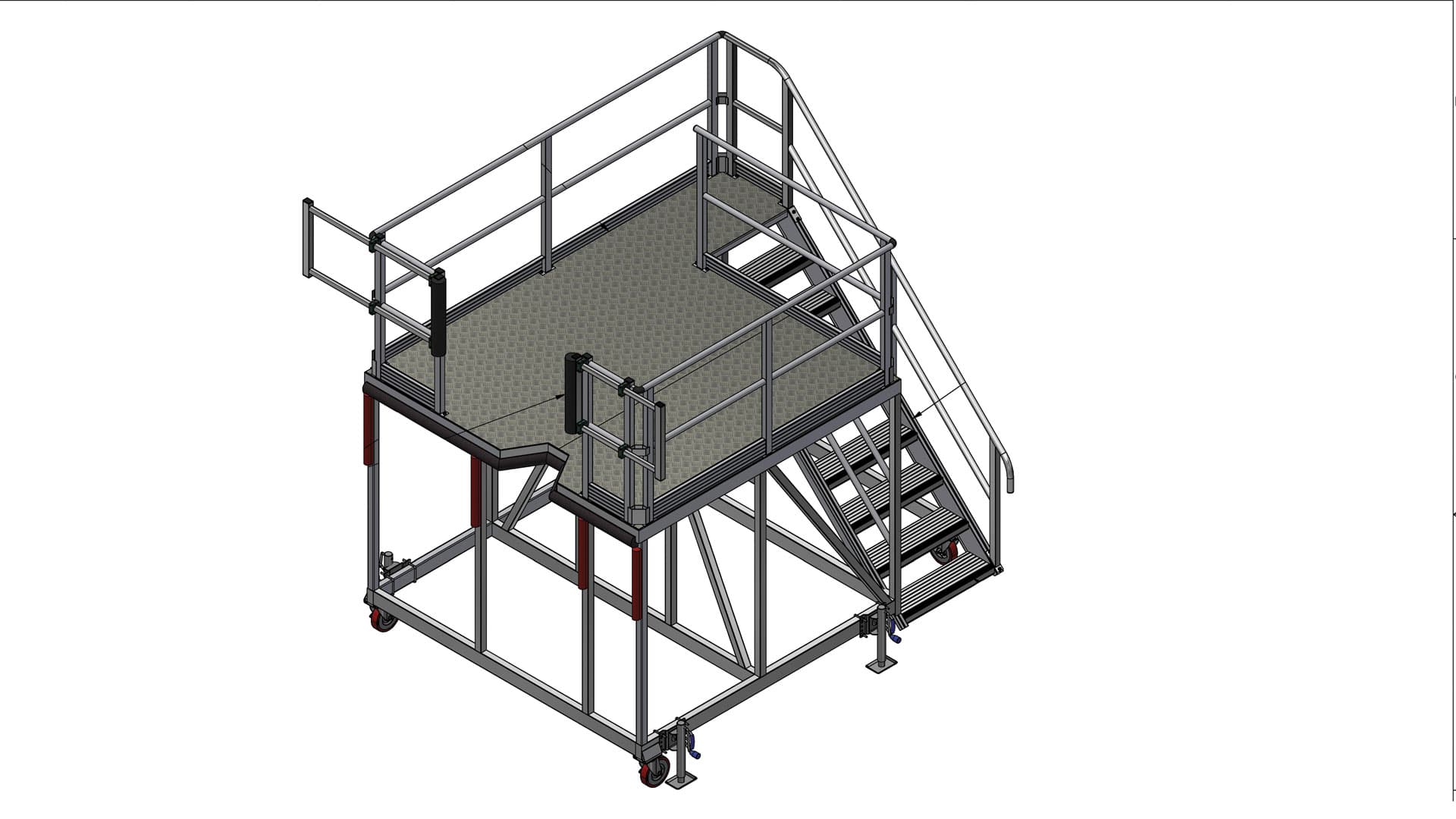

Innovative features include the platform’s precise accommodation of the AW169, specifically integrating with models equipped with the Performance Pack on the horizontal stabilizers. This bespoke contour ensures a flush, secure fit against the aircraft structure, maximizing the working envelope while preserving the airframe’s integrity. Safety is paramount in the design. The leading-edge features include handrails that telescope outward to close any gap between the platform and the aircraft, effectively eliminating fall hazards once positioned. Complementary protective foam is integrated onto these leading edges, safeguarding the AW169’s surface from incidental damage during positioning and use.

Ergonomic Access and Stability

Access to the working deck is facilitated by sturdy stair access, designed to allow users to comfortably carry necessary tools and parts, optimizing the flow and efficiency of maintenance tasks. Once on the AW169 Tail Access Platform, technicians benefit from a secure, stable environment defined by essential safety components: telescopic guardrails provide perimeter protection, while anti-slip stair nosing and high-grip tread plate decking ensure secure footing in all workshop environments. Stability is further assured by wind-down jacks, which allow for precise leveling and firm anchoring of the stand.

Targeted Tail Rotor Servicing

For the Leonardo AW169, this AW169 Tail Access Platform is indispensable for accessing maintenance areas that include the canted tail rotor assembly, where specific side access is required for inspection and servicing. It provides the necessary height and reach for routine inspection of the tail rotor driveshaft, which is subject to canted load stress. Furthermore, the complete access provided to the tail and tail rotor enables thorough routine checks and maintenance procedures, crucial for airworthiness and operational readiness.

Complete Airframe Support

The AW169’s maintenance context includes high-reaching components such as the main rotor hub, engines, and gearbox, all located on top of the fuselage. While this stand is specifically tailored for the tail section, it works in concert with other specialized stands, such as engine/transmission stands and the RotoReach platform, to provide full 360° contoured access to the entire airframe. For complementary side access, consider the Leonardo AW169 Single Level Side Platform. This particular AW169 Tail Access Platform ensures that the required elevation and proximity are achieved for all required work on the rear structure—a notoriously challenging area to access safely and effectively on any helicopter design. By focusing on the tail assembly, this stand contributes significantly to reducing aircraft downtime and enhancing the safety culture during comprehensive servicing cycles. Its durable construction and specific design geometry make it a long-term, high-value asset for maintaining the operational reliability of the Leonardo AW169 fleet.