Elevate B787 Engine Maintenance with the Undercowl Access Platform

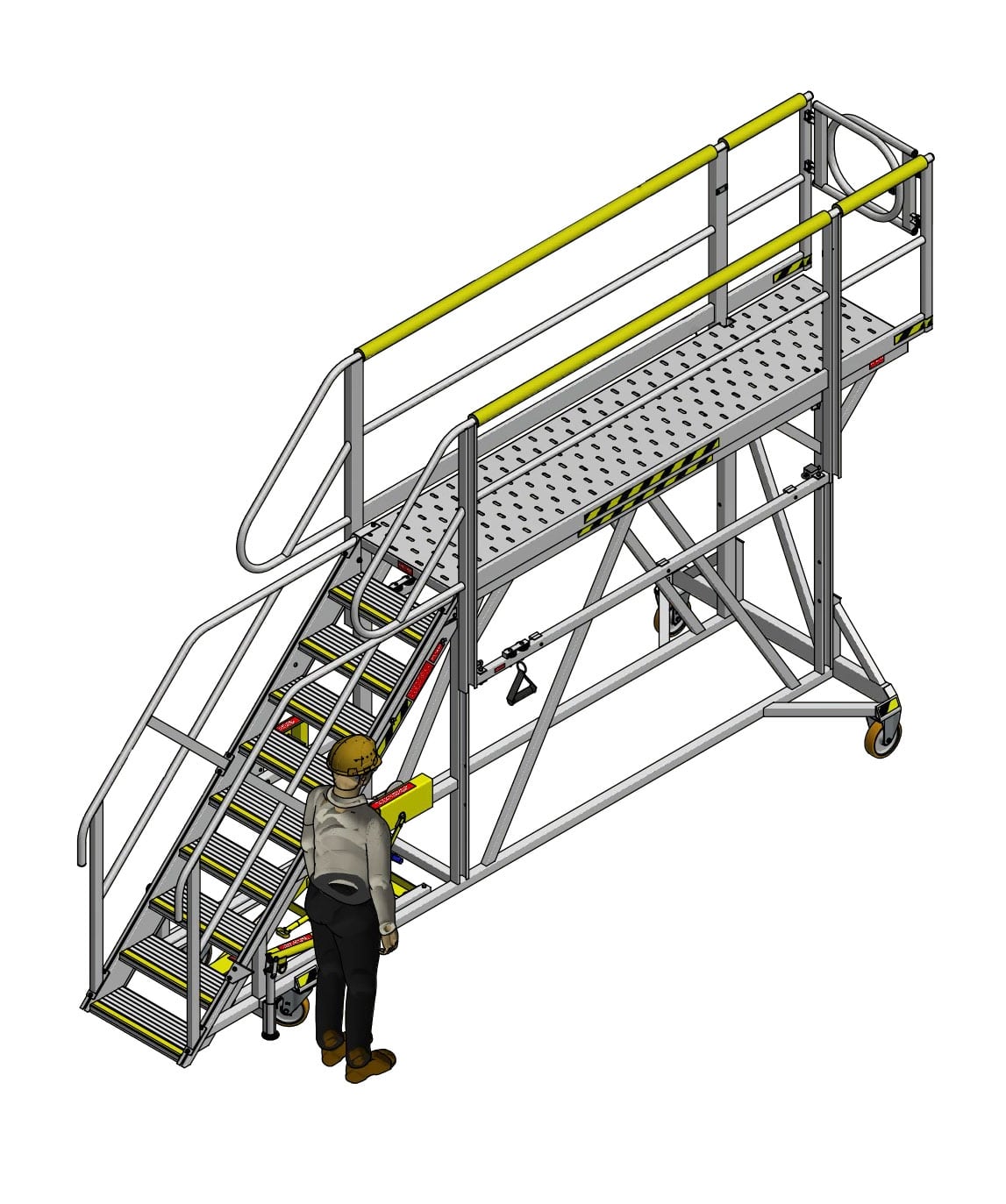

Enhance safety and improve efficiency for Boeing 787 engine maintenance with the specialised B787 Undercowl Access Platform. This bespoke platform is precisely engineered to provide technicians with unparalleled access along the full length of the B787’s engines. It is specifically tailored for external checks and maintenance routines while the engine cowls remain closed. Its design addresses the critical need for a stable, adjustable, and reliable working environment that conforms exactly to the contours and height requirements of the modern wide-body jet engine.

Superior Usability and Safety Features

The B787 Undercowl Access Platform features sliding, height-adjustable guardrails. This feature maximises useability and ensures worker protection across varying maintenance tasks. This adaptability is crucial for maneuvering around complex engine geometry. Safety features are paramount, beginning with self-closing gates that provide a constant physical barrier against falls.

Further protection is offered by pull pins integrated into the handrail structure, acting as a winch safeguard; these pins are disengaged simply by pulling a D-handle. Additional security measures include a magnetic gate catch and a lever brake handle for secure positioning.

Enhanced Mobility and Precision

Built for durability and mobility on the flight line, the platform is towable and wind-rated, maintaining its integrity and stability in dynamic operating environments. Access to the platform itself is designed for ease and safety, featuring 45-degree stair access—the industry standard for comfortable, ergonomic ascent and descent. For maneuverability across the apron, the platform includes a retractable towbar that automatically locks when pulled to the front, facilitating efficient movement between maintenance bays and parked aircraft.

Streamlined Height Adjustment

Height adjustments are streamlined and safe. The B787 Undercowl Access Platform incorporates manual winches on both sides, allowing handrails to be individually raised and lowered with precision. This manual winch system is specifically designed to provide quicker, safer guardrail height adjustment, significantly reducing manual handling and strain compared to less sophisticated systems.

Narrow Footprint for Simultaneous Work

The engineering focus extends to minimising the platform’s physical presence. It features a narrow footprint. This characteristic allows technicians to position stands on either side of the engine simultaneously, optimising workflow and reducing aircraft downtime. The structure’s height and length were custom-made to measure, precisely matching the needs of the Boeing 787 engine configuration. This precise sizing enables technicians to safely scale the entire length of the engine, ensuring no area is overlooked during critical inspections performed with the cowls closed.

Aircraft Protection and Versatility

To protect the aircraft from accidental damage, the top handrail is fitted with a vinyl-covered foam buffer. This attention to detail reflects a comprehensive approach to aircraft asset protection, ensuring the necessary access for maintenance is achieved without compromising the aircraft’s delicate surfaces.

This access solution is versatile, offering different height platforms to suit both inboard and outboard engine positions, with height-adjustable platform options available for absolute flexibility. Consider pairing this stand with the Boeing B787 Inner Cowling Adjustable Height Platform for comprehensive engine maintenance.

Premier Access Solution

By providing a dedicated, custom-fit solution for the Boeing 787, this platform significantly enhances technician safety, improves maintenance efficiency, and supports the operational readiness of the aircraft fleet. It is an indispensable tool for line maintenance and heavy checks, providing reliable, secure access where it is needed most—along the full thrust of the Dreamliner’s power plant.

Its sturdy construction and user-focused features solidify its role as the premier choice for accessing the challenging undercowl areas, ensuring rigorous maintenance standards are met every time. The integrated features for mobility, stability, and height adjustment work in concert to deliver an optimal maintenance experience, turning a complex access challenge into a manageable, safe, and efficient task.