Enhanced Effiency with the H175 Tail Access Platform

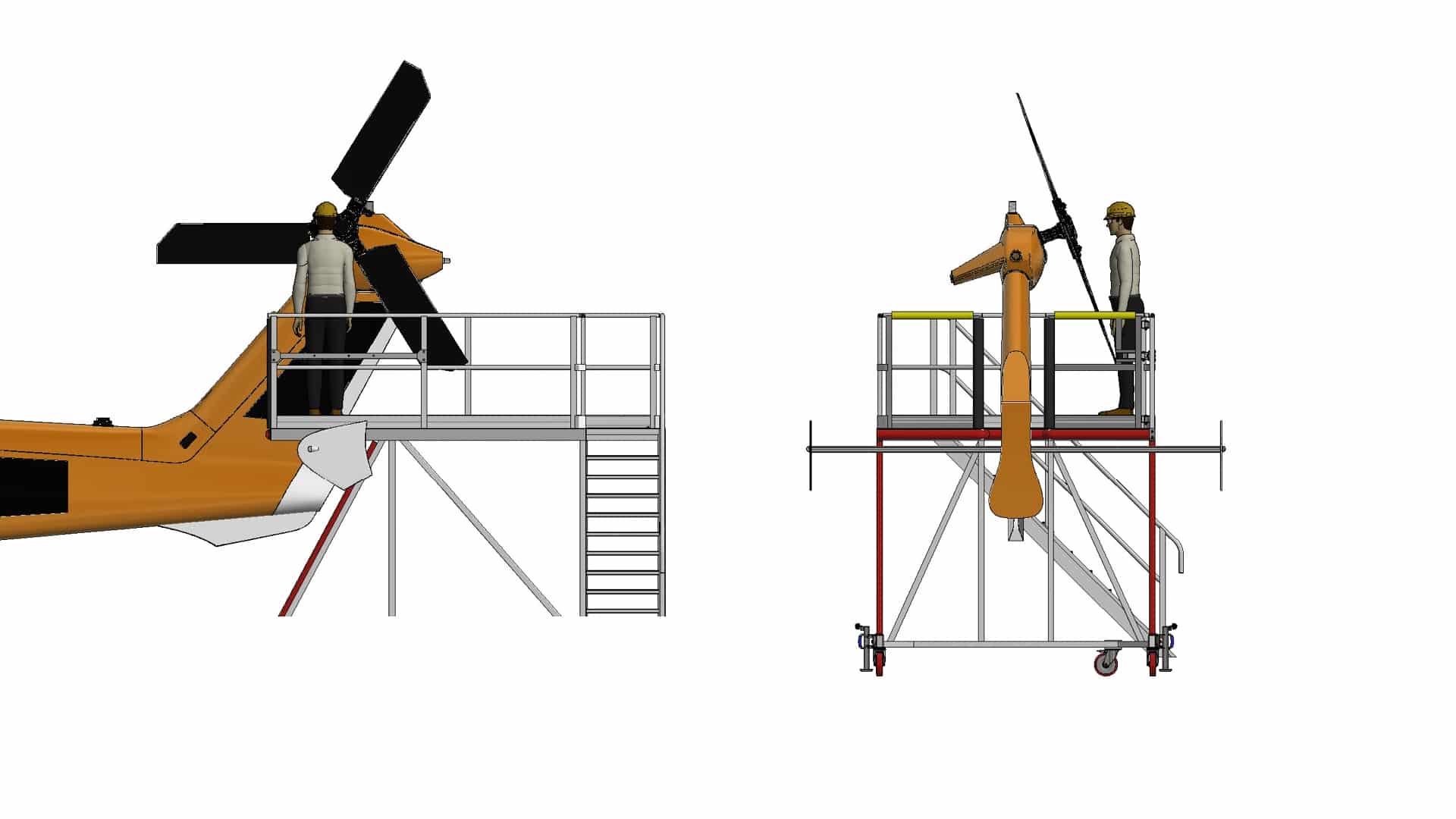

The Airbus H175 Tail Access Platform delivers precision access for maintenance. It provides complete, unhindered access to the most critical and challenging maintenance zones of the Airbus H175 super-medium twin-engine helicopter—specifically the tail section and the conventional tail rotor mounted on the tall T-tail structure. This dedicated access solution resolves the inherent difficulty of reaching the tail rotor hub/gearbox and associated components, areas otherwise impossible to service safely from the ground due to their height.

Safety Features of the H175 Tail Access Platform

Designed as an indispensable tool for routine checks and foundational maintenance activities, this platform significantly elevates operational efficiency and technician safety. Its core function is to eliminate the inherent fall risks associated with working on elevated, complex aircraft structures. The specialized design includes handrails that telescope outward on the leading edge, allowing the platform to be brought precisely against the helicopter’s contours. Once docked, these handrails close the gap to the aircraft, effectively creating a sealed, secure working envelope around the maintenance area.

Rugged Aluminum Construction and Cantilever Design

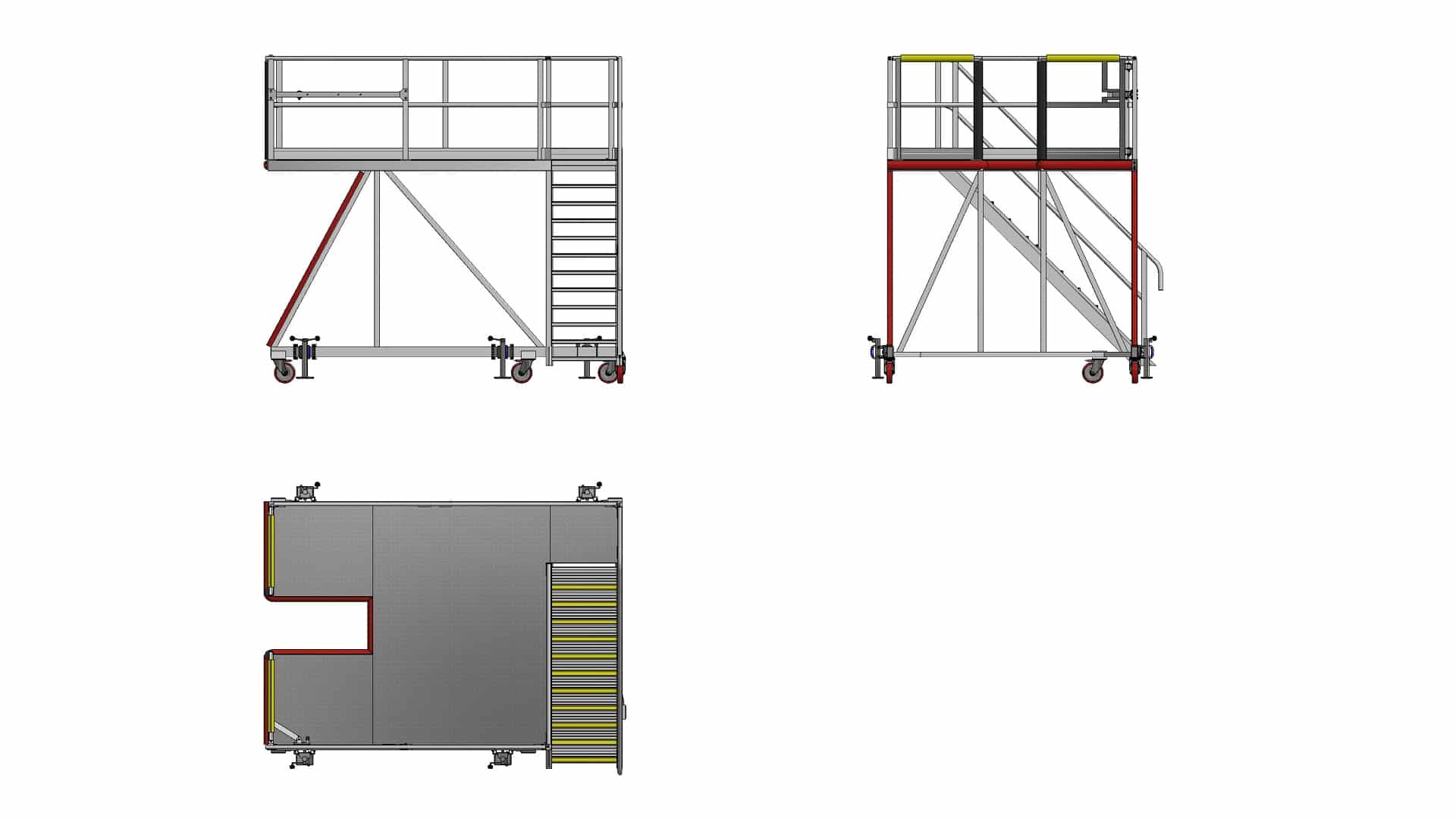

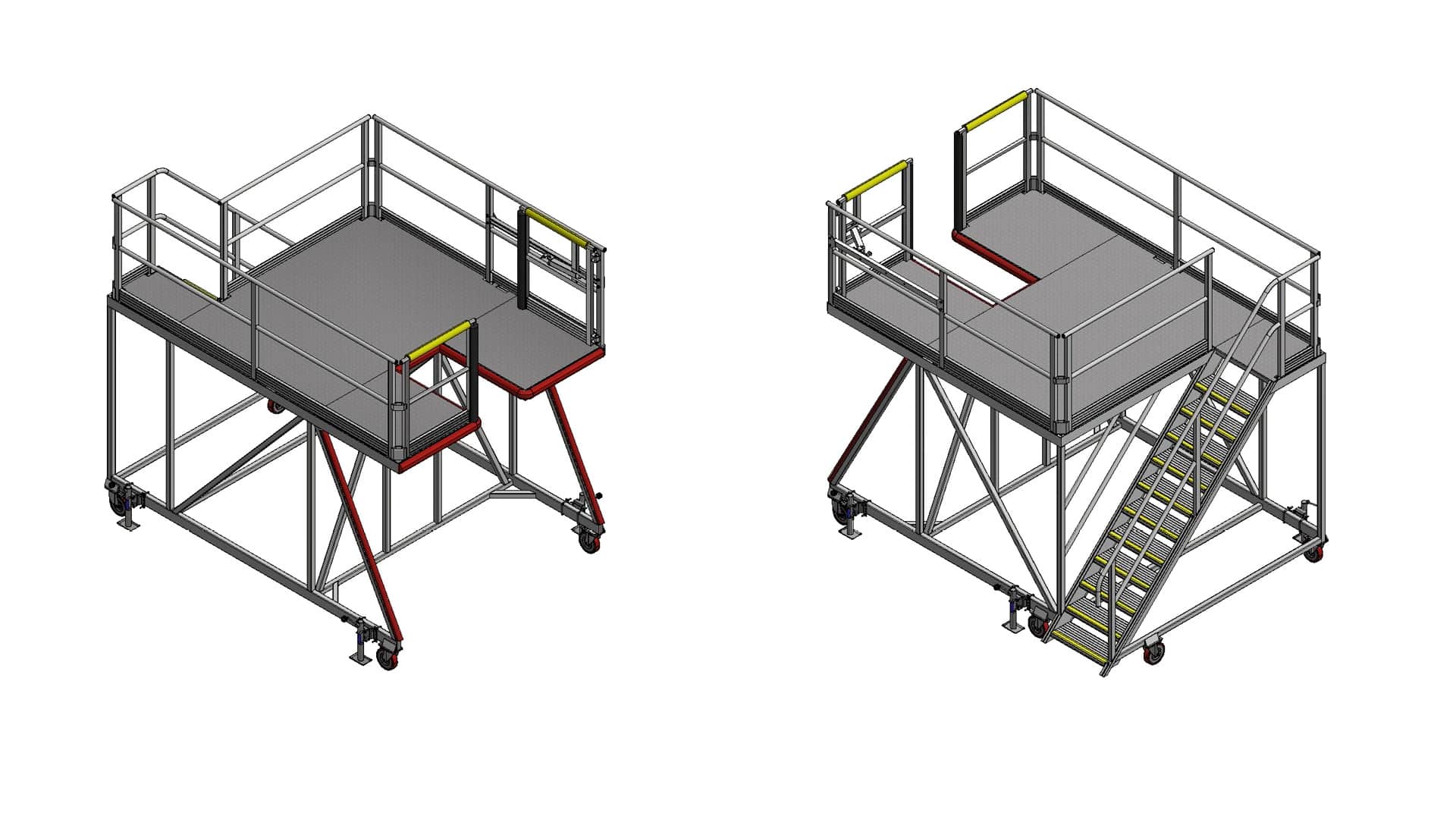

Construction quality is paramount. The H175 Tail Access Platform is fully constructed from a welded, box-section aluminum frame. This sturdy fabrication ensures it is a hard-wearing and effective solution available for comprehensive access to the H175 tail rotor and surrounding structure for all required maintenance activities, including fuel/oil checks, hydraulics inspections, and detailed inspections of the tail rotor hub and gearbox.

A key structural feature is the cantilevered platform design. This innovative overhang is specifically engineered to clear the tail stabilizers, granting technicians uninterrupted access to carry out complex maintenance tasks without structural obstruction. Innovative features include the folding handrail incorporated on the rotor side only. This feature allows the platform to be positioned close to the aircraft while avoiding contact with the main and tail rotors, and once in position, the handrail is securely locked with a spring pin.

Optimized Maneuverability and Stability

Mobility and stability are crucial for an effective access solution in any maintenance hangar environment. The platform is mobile on heavy-duty 200mm diameter locking castors, ensuring easy and precise maneuverability around the H175. For stability, particularly on hangar floors that may be uneven, wind-down jacks are integrated. These stabilizing jacks ensure the platform achieves rock-solid stability during use, eliminating movement and further guaranteeing technician safety while working at height.

Safe and Easy Access

Access onto and off the platform is managed through a 45° stair angle, engineered for safety and ease of use. This stair access features anti-slip grip tread nosing on all treads, allowing users to safely carry necessary tools, parts, and equipment up to the maintenance zone. The pivoting guardrails enhance operational safety; they open when the platform is being moved into position and automatically close to prevent any risk of falls when the platform is actively in use. For comprehensive access to the entire aircraft, consider our Airbus H175 Side Access Platforms.

To protect the aircraft’s structure during positioning and use, all aircraft contact points are shielded by foam and rubber composite buffers. These buffers prevent scratching or damage to the H175’s delicate surfaces, ensuring the integrity of the airframe is maintained throughout the maintenance process. This purpose-built access system targets the high-risk, high-priority inspection areas of the Airbus H175’s tail assembly. It delivers an unparalleled blend of strength, maneuverability, and specialized safety features—such as telescoping handrails, cantilevered deck, and stabilizing jacks—to provide maintenance personnel with the secure and precise positioning necessary for servicing the tail, tall T-tail, and associated rotor components. This platform transforms challenging elevated work into a safe and efficient operation.