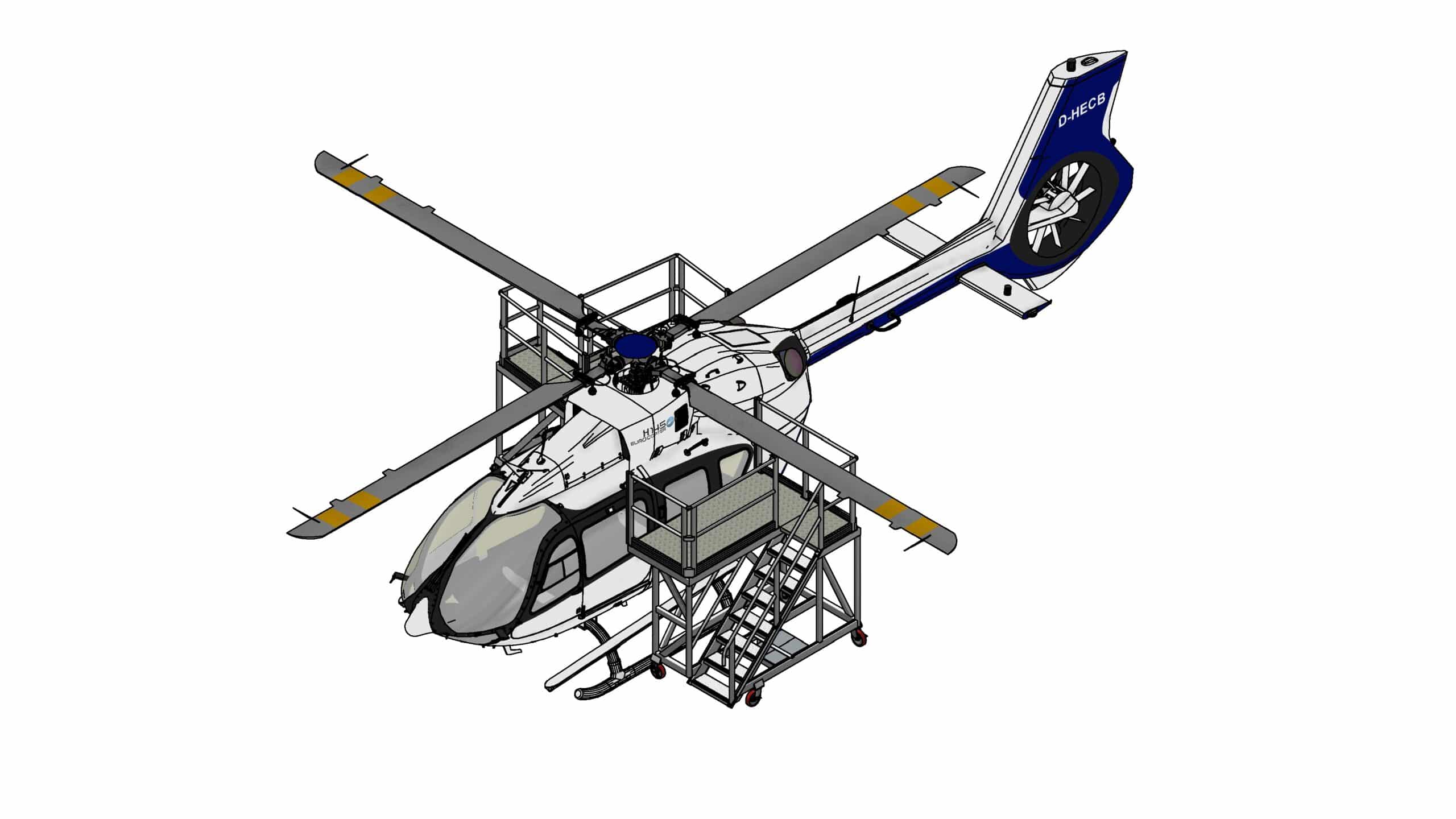

Essential Airbus H145 Flight Line Stand for Maintenance

The Airbus H145 Flight Line Stand is an indispensable access solution engineered for the comprehensive and efficient routine checks and maintenance of the H145 aircraft. This purpose-built platform is methodically designed to support line maintenance activities, offering unparalleled access for technicians performing foundational inspections, adjustments, and repairs on critical external and internal systems.

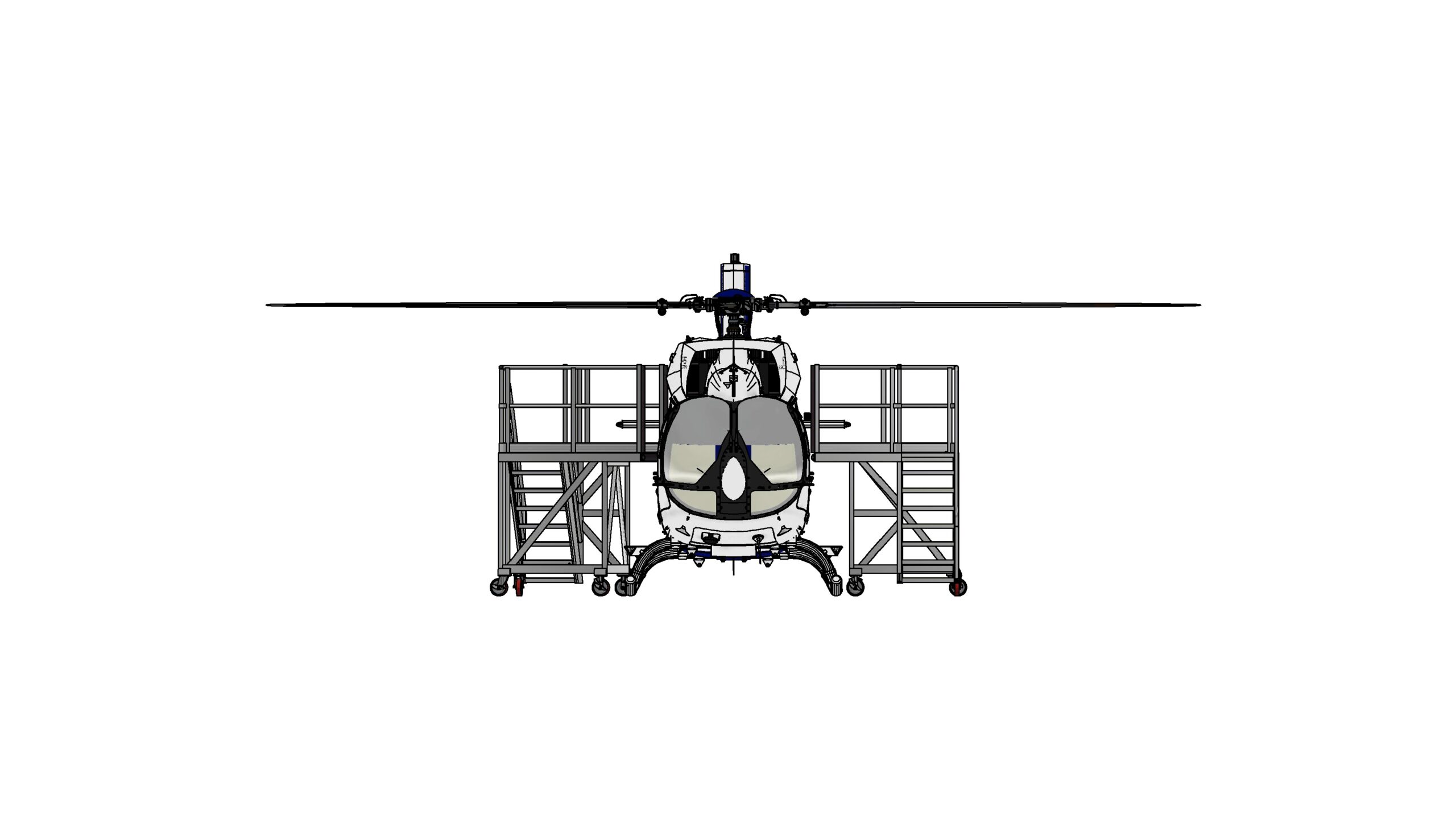

Innovative Cantilever for Skid Clearance

Specifically tailored for the H145, this stand directly addresses the unique geometric challenges of the helicopter’s airframe. Innovative features include the strategically positioned cantilevered section on the leading edge.

Zero Interference Design

This design innovation is crucial, as it allows maintenance personnel to position the stand tightly against the work area while ensuring there is zero interference or clash with the aircraft’s skid landing gear, a common obstruction with conventional platforms. This close proximity capability maximizes the usable workspace and enhances technician comfort and safety.

Universal Dual-Sided Functionality

The versatility of the H145 Flight Line Stand is highlighted by its universal application—it is capable of being used equally effectively on both the left-hand (LH) and right-hand (RH) sides of the H145 aircraft. This dual-sided functionality eliminates the need for two separate dedicated units, streamlining hangar operations and maximizing efficiency during concurrent maintenance tasks.

Comprehensive Airframe Protection

To protect the H145’s delicate surfaces and paint finish, the stand incorporates high-visibility foam buffers. These buffers are integrated into the leading edge of the handrails and the platform itself, serving as critical contact points against the aircraft.

Damage Prevention for Critical Areas

This attention to detail safeguards the airframe from accidental damage when the stand is maneuvered into position, a necessity when working on vital areas like the engine access panels, transmission inspection points, and lower sections of the main rotor hub.

Ergonomic Stairway and High-Traction Decking

Access to the platform is safe and stable, facilitated by 45-degree stairs. This stair angle provides a natural, secure climb, which is far superior to steeper ladders, especially when technicians are carrying tools or parts.

-

Anti-slip Nosing: Applied to all stairs to mitigate the risk of slips or falls.

-

Treadplate Decking: The working deck is constructed from sturdy treadplate, providing strong footing that withstands heavy use and resists spills of oil or hydraulic fluid.

Precision Mobility and Stability

Mobility is assured through a sophisticated castor system. The platform is equipped with a combination of 200mm fixed-size braking directional castors and 200mm side-braking swivel castors.

The fixed directional castors allow for straight-line movement during transport, while the swivel castors enable precise, controlled maneuvering around the tight confines of the aircraft bay. The braking mechanism locks the stand firmly in place once the optimal maintenance position is achieved, ensuring absolute stability throughout the duration of the work.

Targeted Maintenance Access Points

This H145 Flight Line Stand is primarily intended for use during routine line maintenance checks, which often involve accessing the lower and mid-fuselage sections of the H145. Key targeted areas include:

-

Avionics Systems: Rapid access for electronics and systems checks.

-

Fluid Systems: Inspection ports for fuel tanks and hydraulic servicing points.

-

Airframe Integrity: General visual inspections of the composite and metal structures.

By providing an ergonomic, non-obstructive, and highly stable working level, this stand fundamentally improves technician throughput, reduces fatigue, and enhances safety compliance. Consider our Airbus H145 Dual-Level Side Platform for elevated access requirements.