Precision Access for Airbus A350 Engine Change Docking

Accessing the Airbus A350’s large engines requires specialized equipment. This sophisticated wide-body twin-engine long-range airliner, known for its advanced composite design and tall landing gear, demands a precision-engineered platform solution for maintenance. This comprehensive A350 Engine Change Docking system is designed to support maintenance operations, focusing specifically on the complex engine bay, prioritizing technician safety and maximizing efficiency.

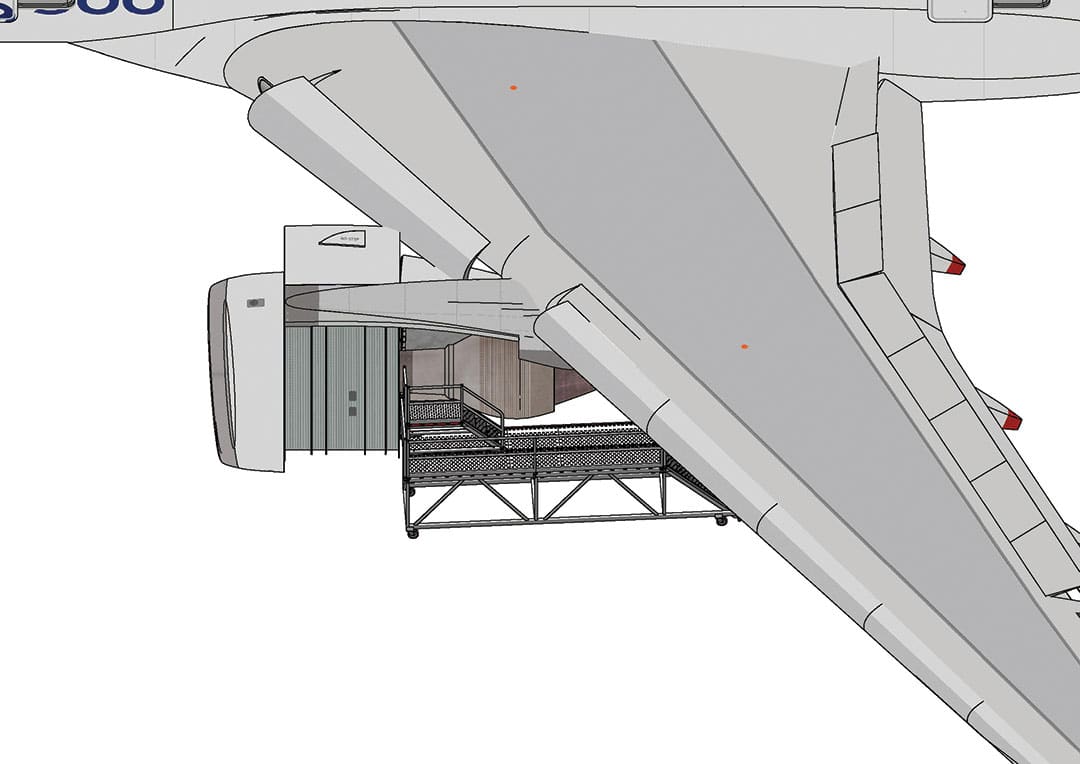

Our specialized A350 Engine Change Docking Platform is engineered for seamless integration with the A350’s engine profile. Innovative features include the use of contoured sliders. These sliders are precisely configured to match the exact curvature and shape of the aircraft engine. This tailored fit creates a tight, secure seal, eliminating hazardous gaps and ensuring technicians can work in complete proximity to the engine cowl and components without compromising safety or stability. This focus on People Safety First is foundational to our design.

Enhanced Mobility and Longitudinal Access

The platform is constructed with functionality at its forefront. It features a step-up stand integrated onto durable roller tracks. This mobility allows the stand to traverse the entire length of the engine assembly. This mobility is critical for maintenance tasks that require longitudinal access, offering high-level access to the top sections of the engine often unreachable from the floor. This capability aids in complex inspections, such as borescoping the engines, and accessing internal areas like AC packs and the avionics bay often inspected concurrently with engine work. This system is designed to be Efficient, saving time and money.

Continuous Full Engine Access

The sliding upper platform is a key design element. This feature ensures continuous, complete access across the full length and height of the engine structure at all times, regardless of the technician’s position. This mobility is indispensable when addressing maintenance areas around the engine inlets (fans, debris) and performing structural inspection (composite damage) near the power plant. The ability to glide the platform sectionally along the engine maximizes workflow, reduces repositioning time, and ensures all high work areas are easily reachable.

Contour-Matching Sliders for Security

The system’s adaptability is enhanced by its protruding sliders that emerge from the side of the main platform structure. These sliders are instrumental in tracing the specific contours of the engine nacelle, providing secure footing right up to the access points. This close access is indispensable for tasks such as checking engine oil levels and conducting physical checks of various engine components.

Reversible Design for Port and Starboard Sides

Understanding that maintenance must accommodate both port and starboard sides of the aircraft, this platform incorporates reversible handrails. This critical design choice allows personnel to quickly and safely reconfigure the entire platform structure to interface with either side of the engine and aircraft fuselage. This versatility significantly reduces the need for duplicate equipment, streamlining hangar logistics and maximizing the utility of the system across the A350 fleet. Our Creative problem-solving ensures a flexible, unified solution.

In A350 maintenance, tasks range from verifying fuel and hydraulic levels via the centralized maintenance system to structural inspection for composite damage. Precise access is non-negotiable. This platform addresses multiple high-reach challenges inherent to the A350—from working on the large engines to accessing upper fuselage areas for antenna maintenance, and assisting during critical engine access procedures.

For other A350 engine access stands, view our full range. It acts as an indispensable component of the safety strategy, providing certified fall-protection platforms required for all work performed at height, including areas like the wing root leading edge, which are too high to reach from the hangar floor. This comprehensive access system elevates safety and productivity for all A350 Engine Change Docking and maintenance operations.