Elevate with AW189 Side Access Platforms

The Leonardo AW189 Side Access Platforms are thoroughly engineered solutions designed to elevate safety and efficiency during the critical base maintenance tasks performed on the AW189 large twin-engine helicopter. These specialized access systems are indispensable for maintenance crews requiring unrestricted and simultaneous access to the aircraft’s main body and upper components.

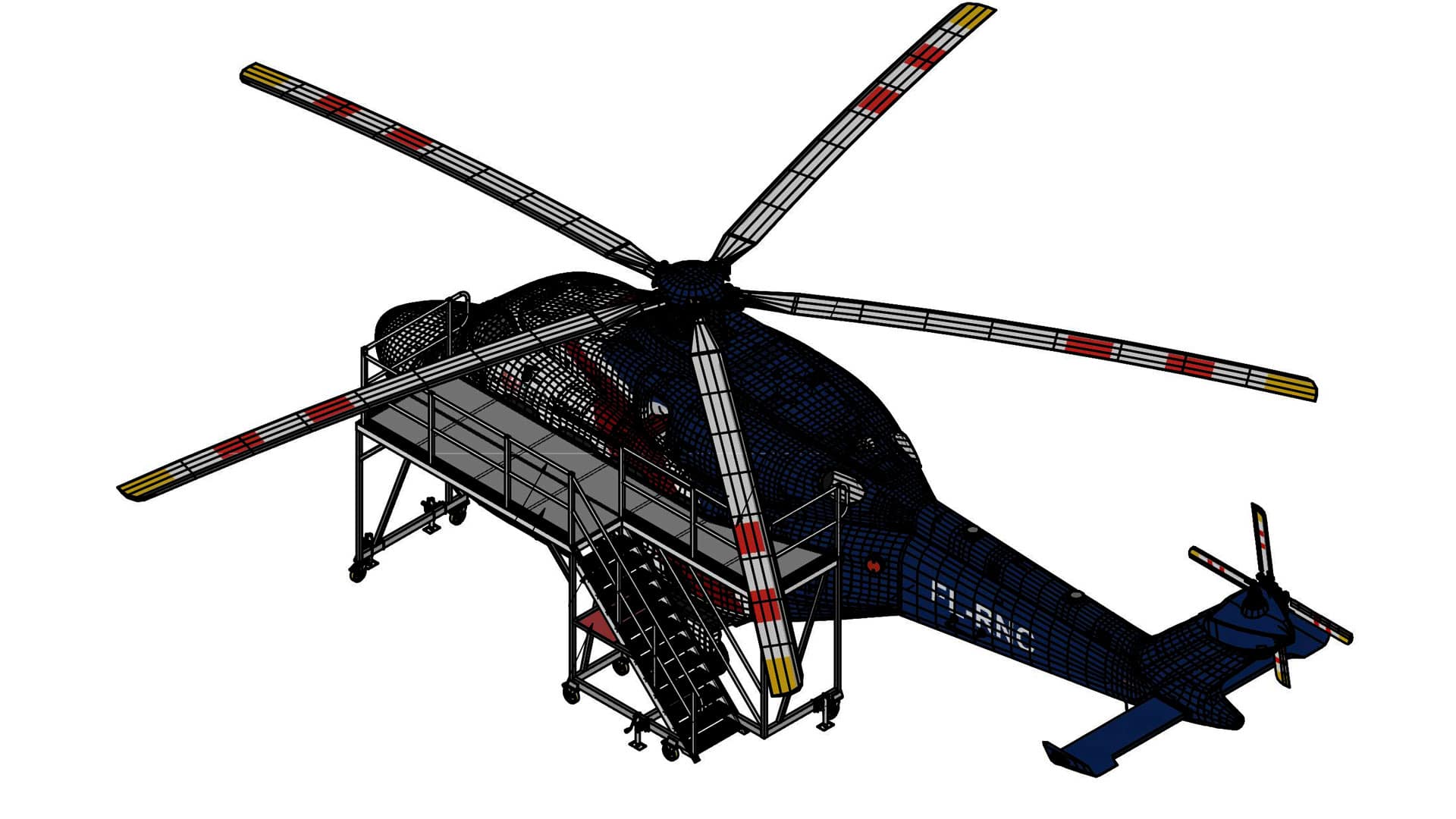

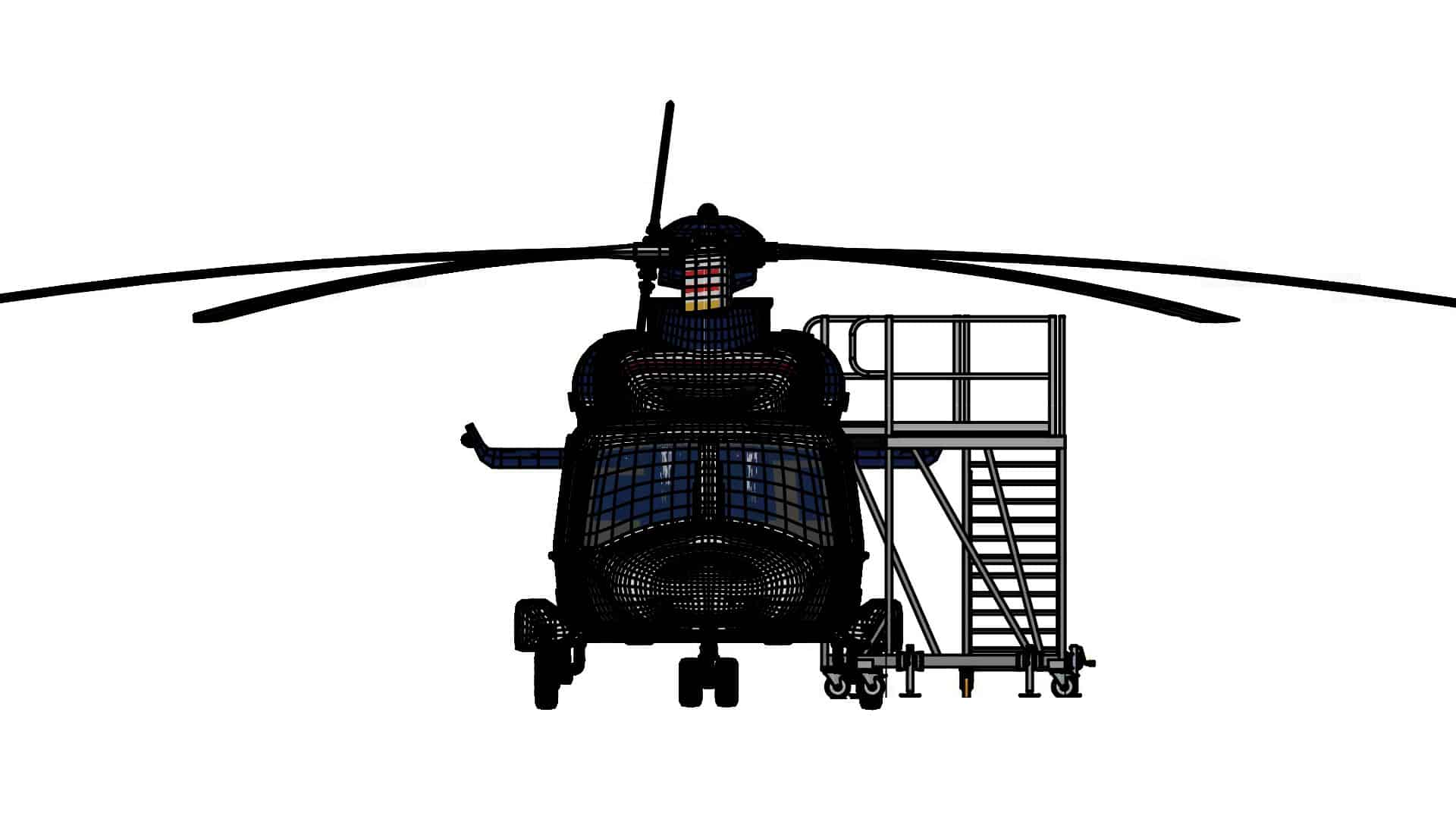

Crafted with a cantilevered and clear span structure, these AW189 Side Access Platforms are unique in their ability to provide a completely unobstructed workspace around the AW189’s fuselage. This design is crucial for conducting complex inspections and repairs, allowing technicians to move freely and access multiple areas without having to reposition the aircraft or the stand repeatedly. The platforms are specifically designed to interface seamlessly with the AW189, ensuring that maintenance personnel can reach the entire side of the helicopter, from the lower fuselage up to the demanding height of the main rotor and engine bays located on top.

Superior Mobility and Unmatched Stability

Mobility and stability are paramount for the AW189 Side Access Platforms. These access structures are equipped with 200mm fully braked swivel castors, enabling effortless positioning and precise alignment next to the aircraft. Once in place, adjustable winding jacks ensure the platform is securely grounded and stable, eliminating any movement during maintenance operations—a critical safety feature when working at elevated heights near sensitive aircraft systems.

Optimized Safety Features

Safety remains the highest priority. Each platform incorporates foundational features such as sturdy handrails and comprehensive toeboards surrounding the large working deck. These measures mitigate the risk of falls and prevent tools or components from inadvertently dropping onto the aircraft or the hangar floor, protecting both personnel and valuable assets. The deck itself is constructed with a durable treadplate surface, providing excellent grip in all working conditions. Furthermore, rubber buffers are installed on all leading edges of the platforms to protect the AW189’s skin from scuffs or damage during docking and maneuvering.

Enhanced Workflow Efficiency

Accessing the elevated work areas is facilitated by a strong 45° access stair. This gradient allows maintenance staff to ascend and descend safely, even while carrying tools, parts, and equipment. This ease of movement significantly improves workflow efficiency, enabling rapid transfer of necessary components to the large working deck where technicians complete base maintenance tasks. A dedicated storage shelf is integrated into the design, providing a convenient place for tools and spares, further streamlining the maintenance process and keeping the working deck organized.

Comprehensive Component Access

Focusing specifically on the AW189’s unique architecture, these platforms are invaluable for addressing the aircraft’s most complex maintenance areas. The clear span structure provides optimal access for working on the main rotor and its transmission system. With the engines also positioned on top of the fuselage, the AW189 Side Access Platforms offer the necessary height and reach to perform detailed inspections, oil system checks (including the engine/gearbox oil systems located on top), and routine upkeep of these vital powerplants.

Mitigating High-Risk Maintenance

Maintenance on the AW189 also involves complex systems like the triple redundant hydraulics and the intricate gearboxes, which require regular checks for vibration and chip detector warnings. These access systems ensure technicians can safely and efficiently reach these high-mounted components. Given that the AW189 is larger and higher than its predecessor, the AW139, access to the roof presents a significant fall risk; these AW189 Side Access Platforms effectively mitigate that risk by providing a secure, high-level working enclosure.

While specialized AW189 platforms exist for engine work and tail maintenance, these Side Access Platforms are the core solution for comprehensive fuselage and upper aircraft maintenance, bridging the gap between nose and tail stands to deliver a full maintenance envelope. Their narrow profile is a major operational advantage, specifically engineered for storage and positioning within compact hangar operations where space efficiency is crucial. This design ensures that the high utility of the platform does not compromise valuable floor space when the stand is not in active use. These purpose-built AW189 Side Access Platforms are critical safety and efficiency tools for maintaining the Leonardo AW189, offering unmatched, simultaneous access to the main rotor, transmission, engines, and side body, ensuring all scheduled and unscheduled maintenance—from routine checks to major component overhauls—can be completed safely and effectively. For a complete maintenance enclosure, consider integrating the Leonardo AW189 Full Surround Docking system.