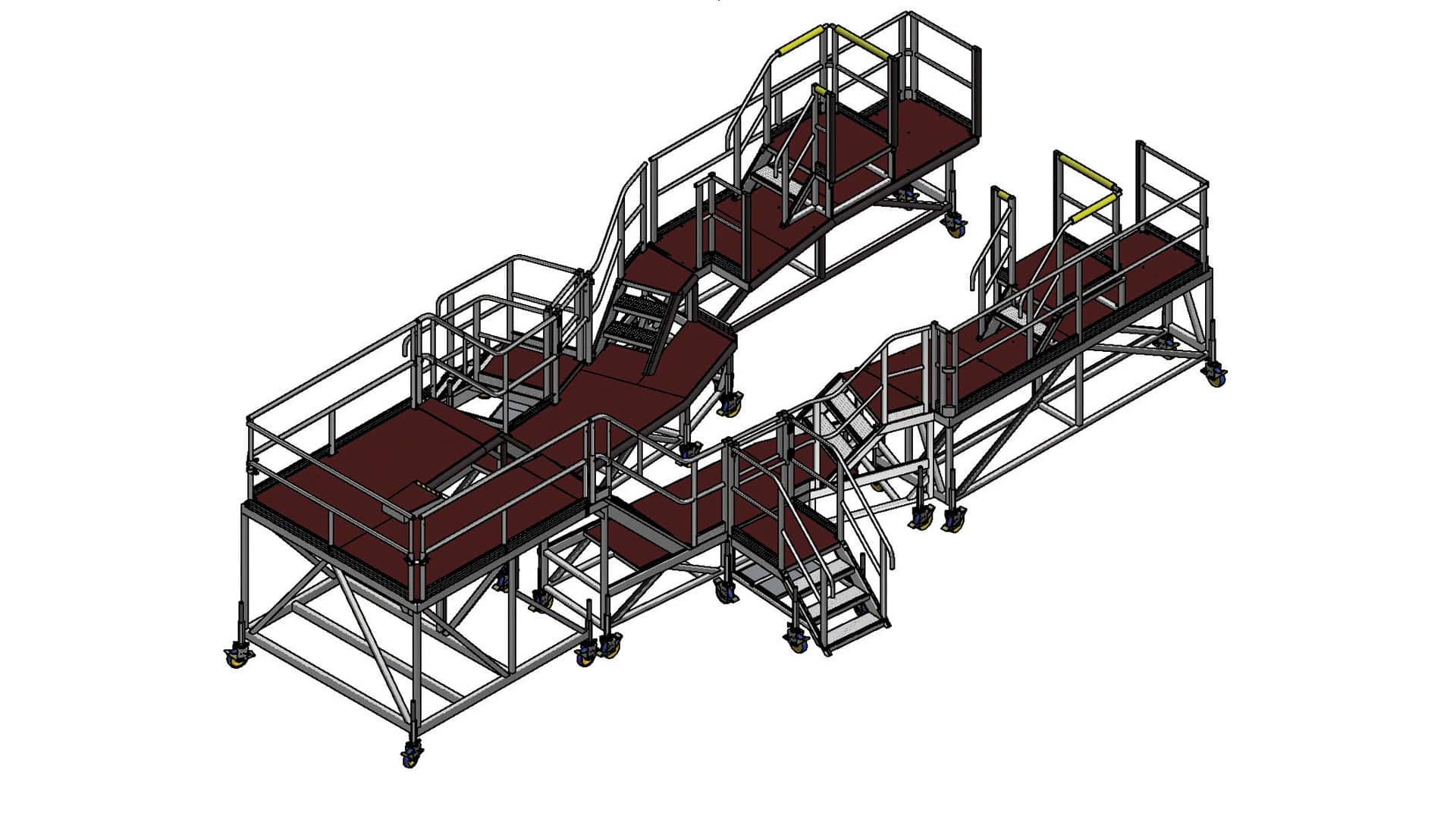

Complete AW169 Helicopter Docking System

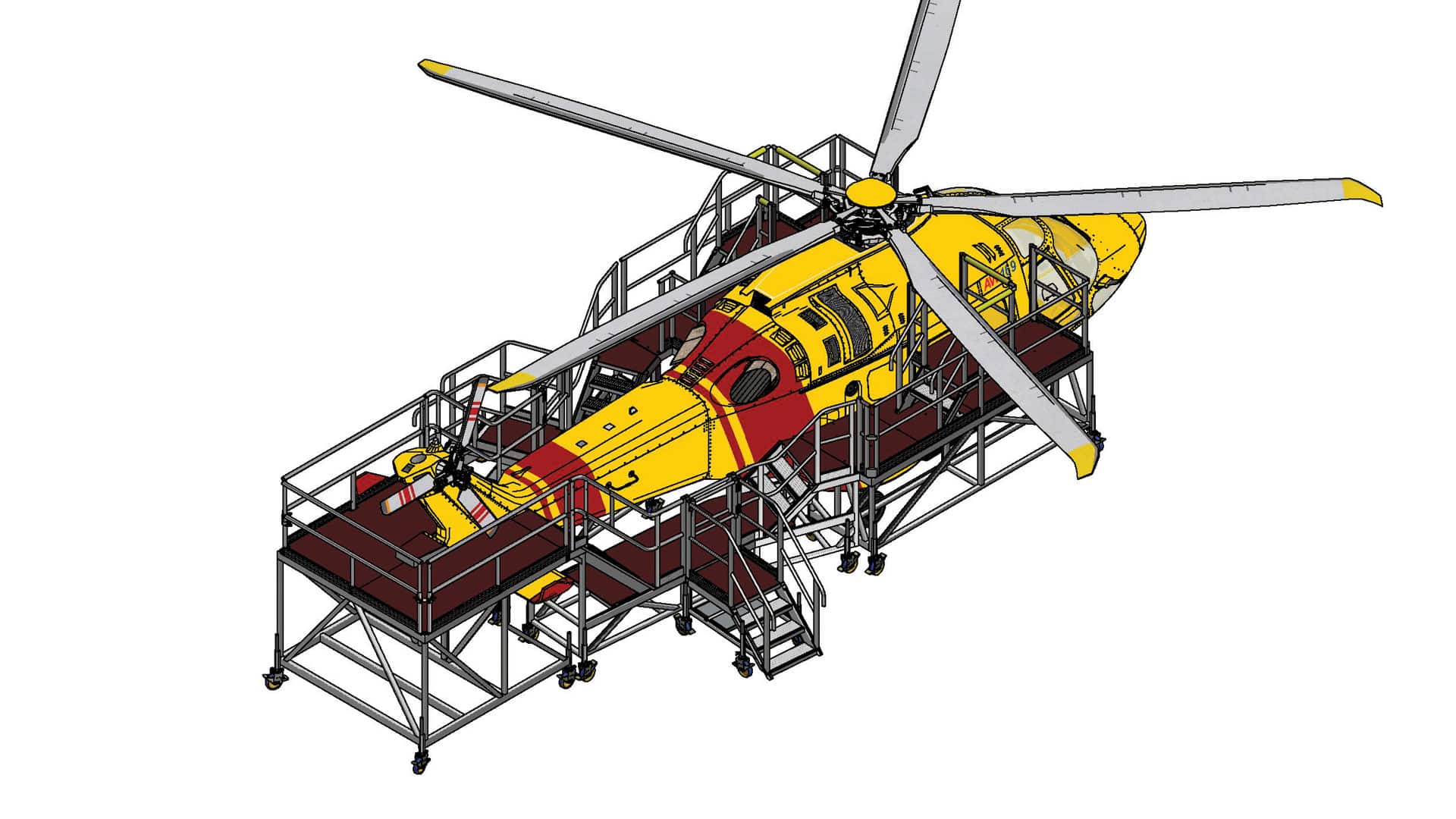

The Leonardo AW169 Helicopter Docking System delivers unparalleled access and safety for technicians maintaining, inspecting, and repairing the light-medium twin-engine rotorcraft. This modular system fully envelops the AW169, ensuring unrestricted access around the helicopter’s entire periphery while providing stable, dedicated working environments for key maintenance tasks.

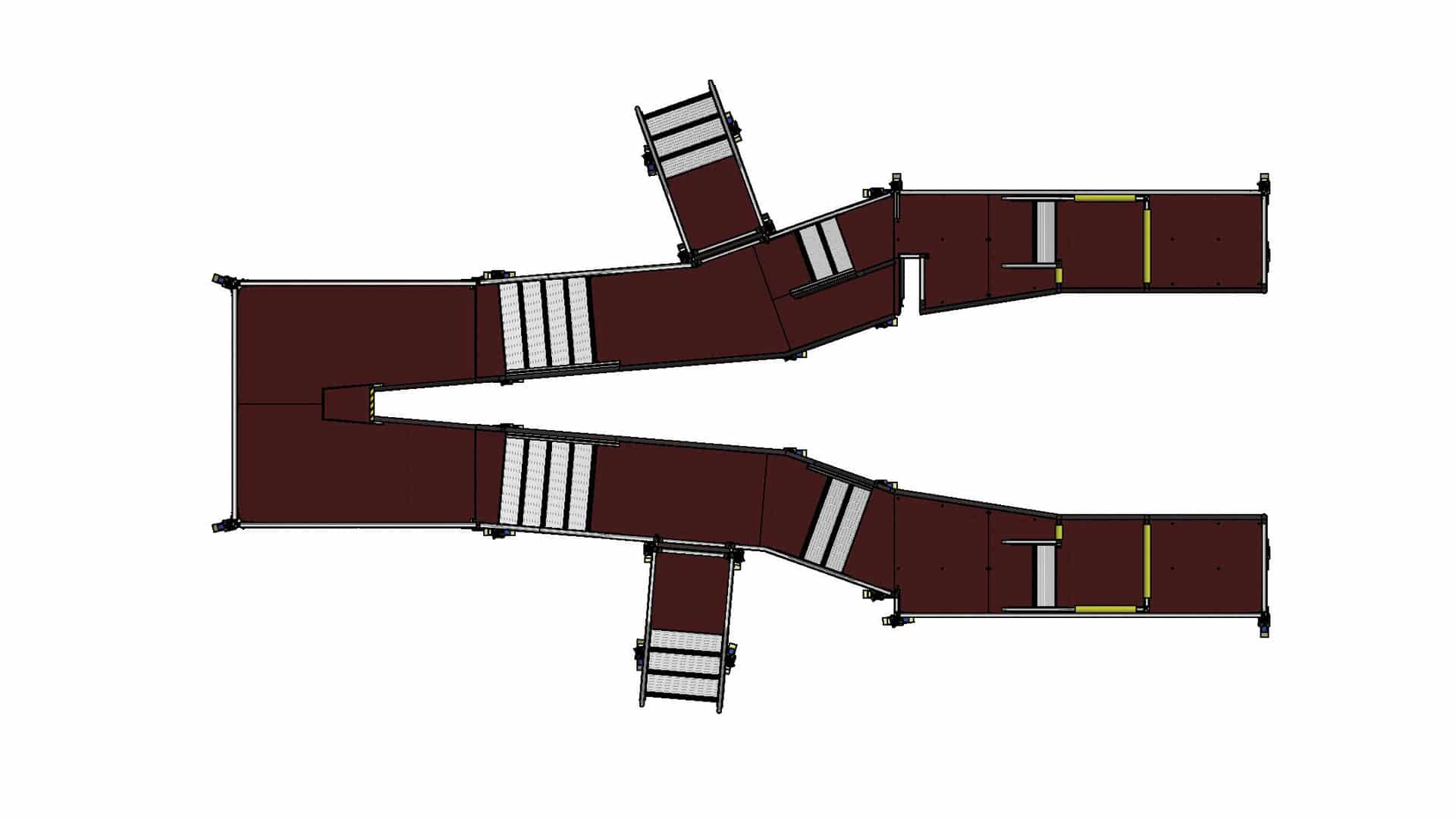

Operational flexibility and ease of deployment are central to this AW169 Helicopter Docking System. The entire docking structure consists of independently mobile modules. This mobility facilitates rapid pack-down for compact storage when not needed and swift, efficient deployment for maintenance cycles. We focus on what works, ensuring your team is safe and productive faster. The system incorporates several specialized platforms, each designed methodically to address specific access challenges of the AW169’s unique architecture.

Specialized Access for AW169 Maintenance

The LH Step Up Platform serves as a primary access point, providing the required elevation to safely reach the main body and lower roof areas on the left-hand side. This elevation is foundational for preparatory inspections and accessing lower panels.

Tail Rotor and Empennage Access

Maintenance on the aircraft’s empennage uses the Tail Platform and the RH Side Tail Boom Access Platform. The Tail Platform offers a broad, secure area for technicians working on the tail rotor assembly and the driveshaft system. Given the AW169’s canted tail rotor, which requires approach from the side, these platforms ensure safe, level footing for critical inspections of the tail rotor and the full length of the tail boom structure on the right-hand side. This focused access is necessary for checking the tail rotor driveshaft, which operates under canted loads, and for general airframe inspection in this vulnerable area.

Engine and Transmission Platform Security

The main power and transmission components are positioned atop the fuselage, a significant height challenge—approximately 2 to 2.5 meters high. The AW169 Helicopter Docking System addresses this with the dedicated RH Side Engine Access Platform and the LH Side Engine Access Platform. These sturdy platforms provide elevated, contoured working zones specifically for tasks related to the aircraft’s two powerful Pratt & Whitney Canada PW210A engines and the main gearbox/transmission system. Maintenance activities include checking engine oil levels, refueling checks, servicing filters, and inspecting the hydraulic systems and main rotor hub—which, being a composite structure, requires close, stable inspection access. These platforms are engineered to be used as engine/transmission stands, allowing technicians to work comfortably and securely at height.

Comprehensive Coverage of the AW169 Helicopter Docking System

The overall design is complemented by the Mobile Dock Access Platform, a flexible unit that can be positioned anywhere around the aircraft to fill gaps or provide supplementary access, ensuring comprehensive 360° coverage. When all modules are deployed, the system creates a contoured stand that completely surrounds the helicopter, eliminating unauthorized access routes and enhancing safety during all phases of maintenance. For alternative solutions, consider our specialized single-level platforms for the AW169.

Main Rotor Inspection with RotoReach

The system also allows inspection of the 4-blade main rotor and facilitates safe height access for tasks like reaching the roof of the cabin and the main rotor hub components. The integrated RotoReach platform concept specifically assists in safely reaching the outer extremities of the main rotor blades for detailed checks, which is vital for maintaining the aircraft’s performance and safety compliance. This purpose-built AW169 Helicopter Docking System is indispensable for maintaining the AW169. It replaces temporary, unstable access solutions with a permanent, integrated, and highly mobile working environment that directly supports the demanding maintenance requirements of a modern twin-engine helicopter, focusing particularly on elevated components like the engines, transmission, and main/tail rotors.