Custom Access for the E190 Narrow-Body Jet

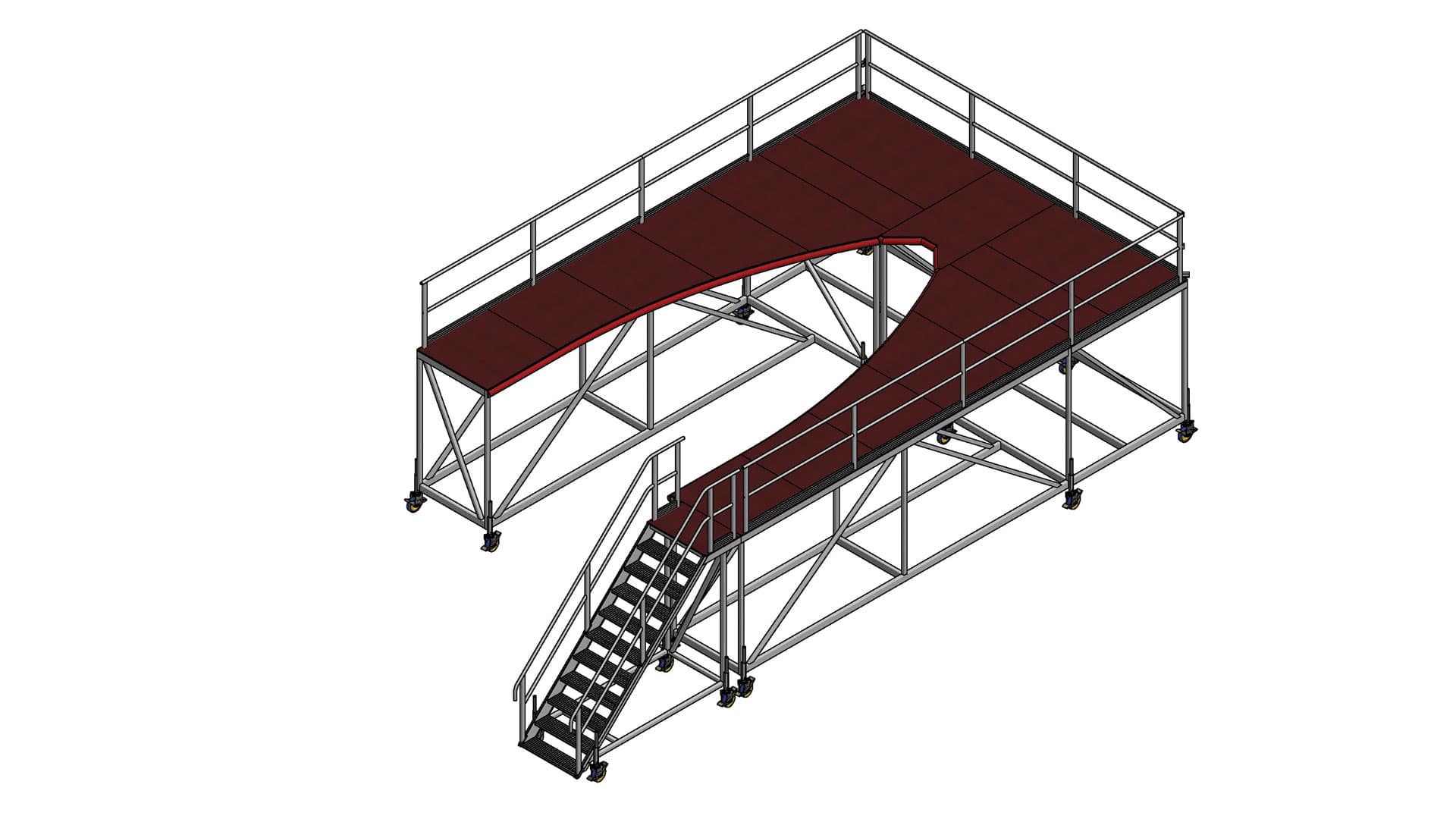

The E190 Wrap-Around Nose Dock is a detailed access platform. It is purpose-built to integrate seamlessly with the E190 narrow-body regional jet. Recognizing the specific access challenges of this aircraft class, this platform ensures comprehensive, ergonomic, and safe coverage for foundational maintenance tasks at the airframe’s forward section.

Unobstructed Access and Enhanced Safety

This platform’s primary function is to provide safe, unobstructed, and continuous access to critical areas of the aircraft’s nose. The wrap-around configuration allows technicians to work simultaneously on the windshield and primary entry doors, facilitating necessary inspections, repairs, and servicing. There is no need for repositioning multiple smaller stands. The profiled deck is contoured for a snug fitment around the fuselage. This eliminates hazardous gaps between the platform and the aircraft skin. This close-fit design prevents accidental drops and maximizes technician safety and comfort. This contributes to increased efficiency during maintenance checks.

Adaptable Height and Secure Ascent

Innovative features include the height adjustable option. This capability is paramount for the E190 Wrap-Around Nose Dock. It allows the platform to be rapidly adjusted whether the aircraft is positioned on its landing gear (wheels-on-the-ground) or elevated on jacks. This flexibility ensures that optimal working height is always maintained. This reduces strain and improves visibility for maintenance personnel, regardless of the phase—from simple line checks to more extensive heavy maintenance checks.

Access to the working deck is facilitated by 45° stair access. This stair angle provides a safer, more natural ascent and descent compared to steeper ladders. This is particularly important when technicians are carrying tools or parts. The design minimizes fatigue and helps prevent slips and falls. This is a significant consideration given the high-cycle nature of regional jet operations.

Targeted Servicing Areas

For E190 maintenance, this E190 Wrap-Around Nose Dock is indispensable for servicing high-priority areas. The nose section houses crucial sensors and avionics infrastructure. Technicians gain immediate, stable access to inspect and service the pitot-static probes and other sensitive nose-mounted sensors. Furthermore, the platform’s position is ideal for tasks related to the flight deck, specifically windshield cleaning, inspection, or replacement procedures.

Comprehensive Forward Fuselage Coverage

Beyond the immediate nose, this comprehensive access solution supports activities often performed concurrently. The maintenance context of the E190 involves several intertwined systems located nearby or accessed via the forward fuselage. The platform facilitates easy access for refuelling checks and the servicing of hydraulic system ports often located in the forward bay areas. The high-reach capability, enabled by the height adjustment, can also offer a stabilized working area for certain checks involving the forward ECS (Environmental Control System) packs, situated under the belly of the aircraft.

For heavy maintenance phases, the E190 has its avionics bay (E-Bay) situated forward of the wing box. External structures surrounding this area, including hatches and covers, often require inspection and maintenance that the nose dock efficiently supports.

Efficiency in Line and Heavy Maintenance

When considering the overall maintenance environment for the E190—a narrow-body regional jet—speed and safety are paramount. The design philosophy behind this wrap-around dock is to provide a single, sturdy, and intuitive structure. It replaces the need for several smaller, less stable general-purpose access stands. It centralizes the workspace for key maintenance checks on the forward fuselage. This ensures that tasks like routine inspections, visual checks of tires and brakes, and localized hydraulic checks can be completed with maximum efficiency and minimal setup time.

The durability and modularity of the design ensure this specialized access equipment can withstand the demanding nature of both hangar-based maintenance and high-frequency line maintenance environments. It is a fundamental asset for MRO facilities focused on maintaining the operational readiness of the Embraer E190 fleet, delivering an unparalleled level of safety and precise access for all forward-fuselage servicing requirements. You may also be interested in our Embraer E190 Aircraft Passenger Boarding Stairs for ground operations.