Efficiency with the H135 Side Access Docking Platform

Improve your operational safety and efficiency with the Airbus H135 Side Access Docking Platform. This purpose-built system is methodically engineered for precision maintenance on the H135 helicopter. This advanced, hand-manoeuvrable platform replaces unstable step ladders and generic access methods, providing sturdy, secure, and comprehensive coverage of critical service points on the aircraft.

Tailored for H135 Maintenance

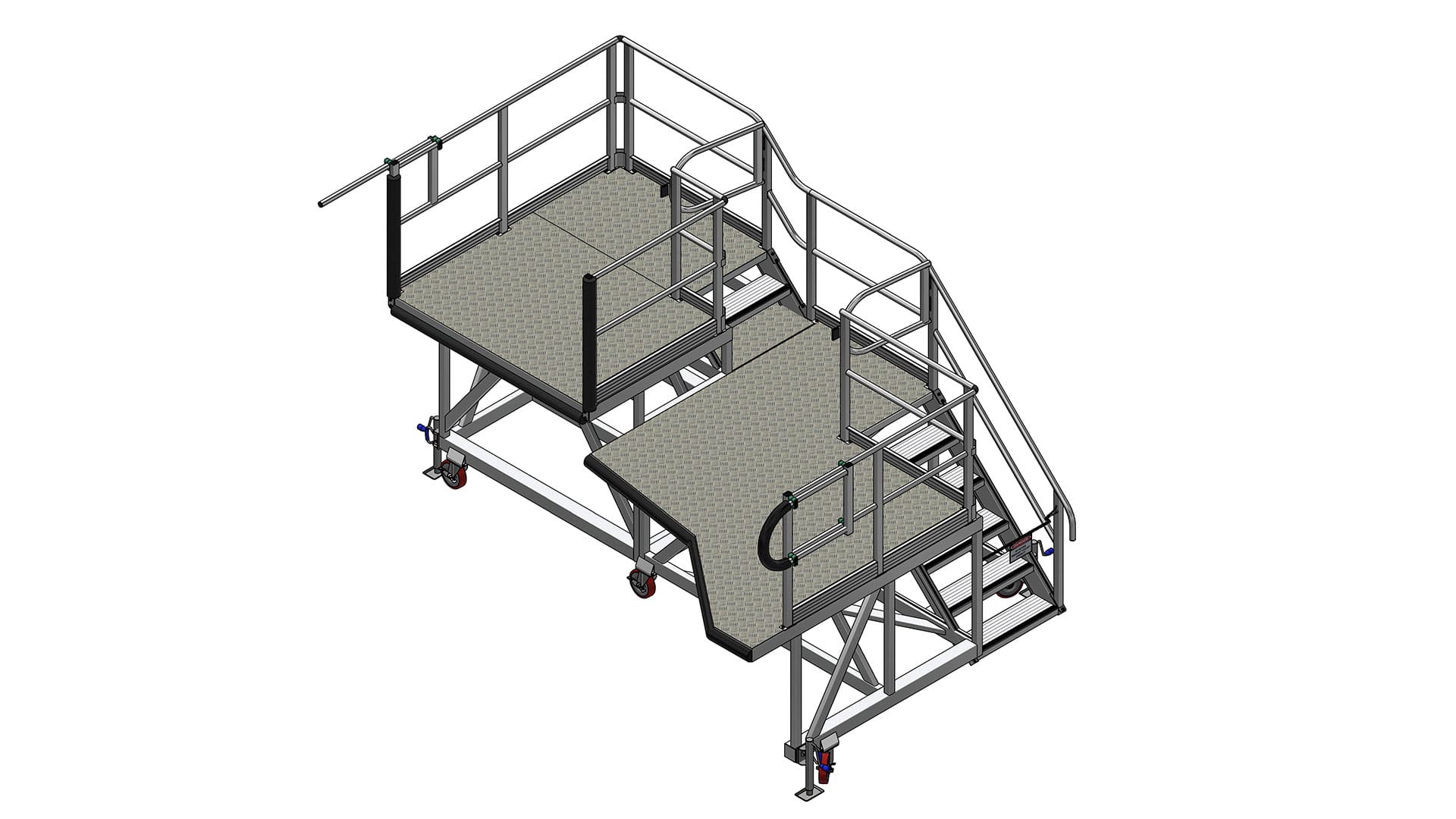

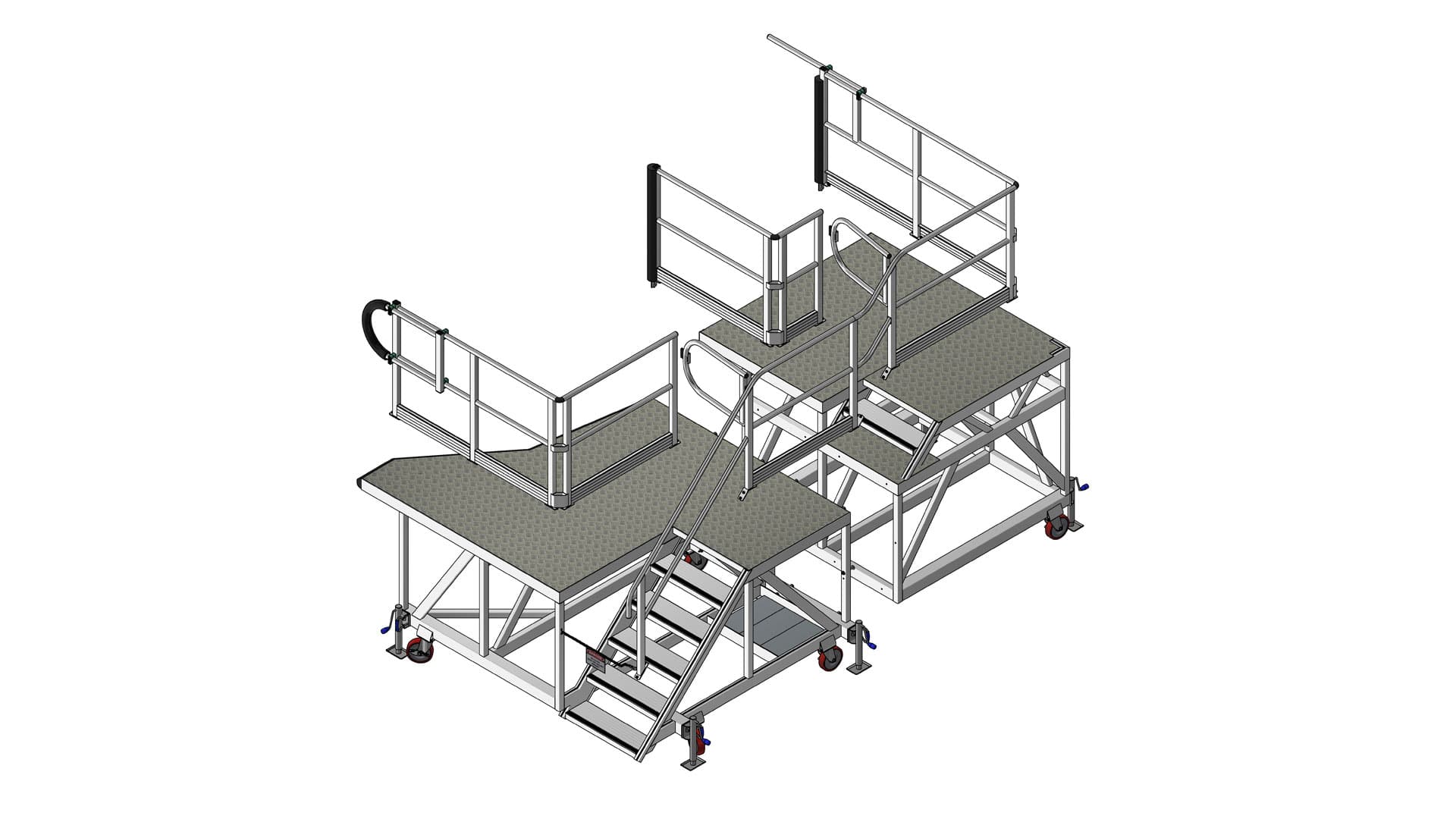

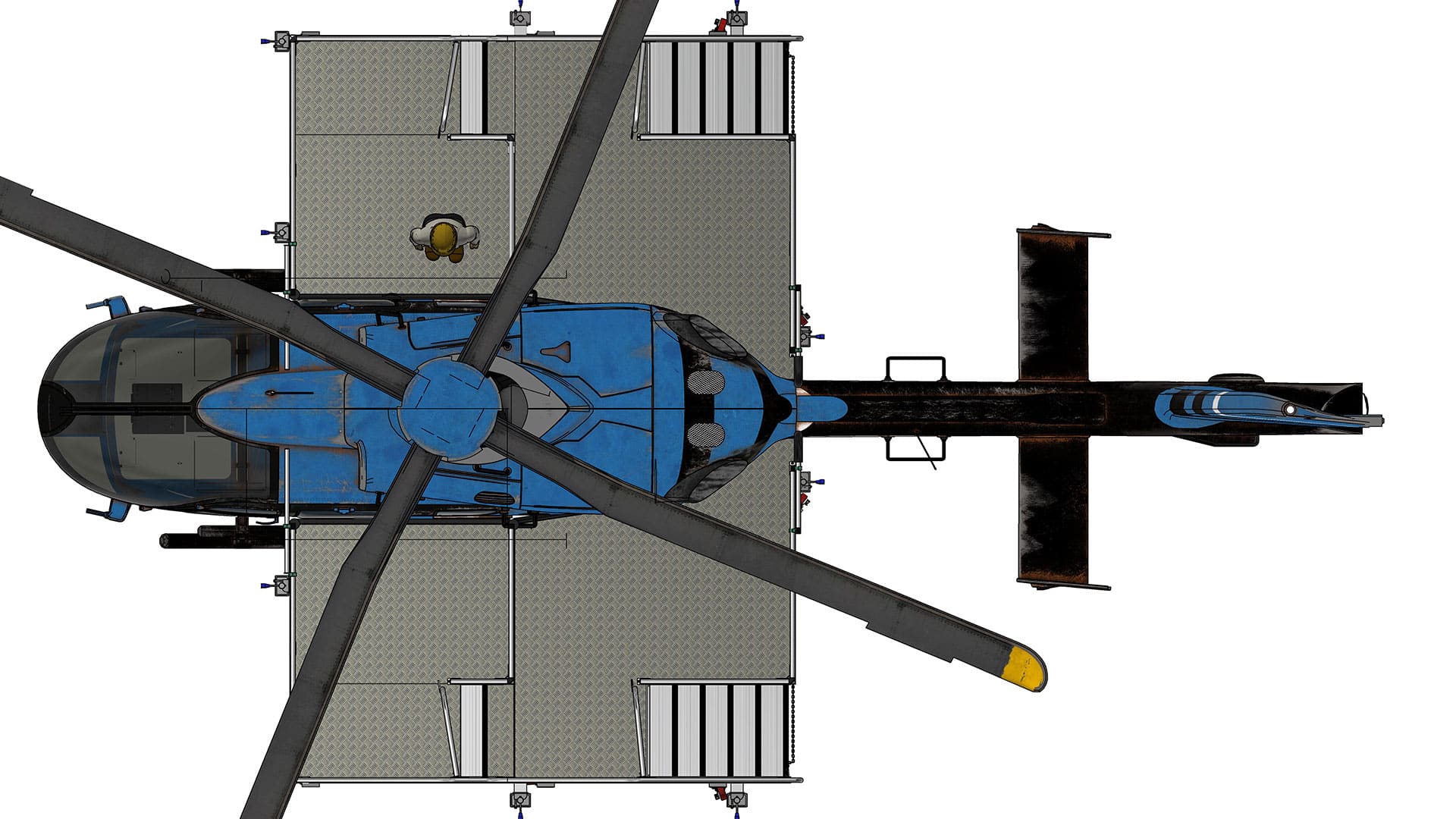

Tailored specifically for the Airbus H135, this platform system addresses the unique structural geometry of the helicopter, particularly the slope of the upper fuselage. Recognizing the need for varied heights, the system features two distinct levels integrated into the platform design. This crucial dual-level arrangement ensures ideal and safe positioning for technicians accessing both the top engine area and the higher rotor head. Achieving precise elevation at these two critical maintenance locations eliminates the need for precarious stretching or climbing. This dramatically reduces fall risk and enhances task completion speed and quality, focusing on our core value of Safety First. For alternative H135 access, consider the Airbus H135 Nose Access Platform.

Durable and Lightweight Construction

The structure is fabricated from high-tensile aluminum, a material chosen for its first-class balance of durability and lightness. This high-tensile alloy ensures the platforms are weather-resistant, capable of withstanding demanding flight line environments. It remains light enough for quick, manual repositioning around the aircraft by maintenance personnel. This ease of movement is foundational for dynamic maintenance schedules, aligning with our commitment to being Efficient.

Unmatched Safety and Ergonomics

Accessibility and safety features are paramount to the design. Accessing the platform is made safer and more balanced via 45-degree stairs, which offer a far more stable ascent and descent compared to traditional step ladders. The deck itself is fitted with Treadplate Decking and Anti-slip Nosing, providing exceptional grip in all conditions.

Secure Access and Mobility

To manage personnel movement, the platform incorporates both entry and exit gates: Half Height Batwing Gates at the Entry point and Full Height Batwing Gates at the Exit, both secured with magnetic latches for secure, self-closing operation. A “No Entry Sign” attached to a high-visibility chain further reinforces safety protocols at designated access points. For movement on paved hangar floors, the platform rests on 200mm Swivel/Side Braked Castors. When operations shift to rougher or uneven terrain, the platform’s versatility is maintained through the integration of 260mm solid rubber wheels paired with tough wind-down jacks. These jacks allow the platform to be secured firmly and leveled precisely, ensuring absolute stability regardless of the ground surface.

The platform’s physical design also includes a large side cantilever. This deliberate engineering feature is crucial for clearing the helicopter’s skids at ground level, allowing the platform to be positioned intimately close to the fuselage without interference, maximizing the usable work envelope. Innovative features include a protective foam lining. This feature safeguards the delicate surfaces of the Airbus H135, preventing accidental scratches or damage during docking and maintenance procedures. The platform is rated for a 500kg (1100lb) Safe Working Load (SWL), providing ample capacity for technicians, tools, and necessary spares. The H135 Side Access Docking Platform is designed to be highly versatile, available in three standard platform heights (0.95m, 1.7m, and 2.3m).

This makes it suitable not only for the H135 but adaptable for various flight line maintenance applications across different helicopter models where precise side access is required. While compliant with AS1657 standards, this access system can be manufactured to meet virtually any regional safety and engineering regulation globally, guaranteeing seamless integration into any maintenance operation. This commitment to specific aircraft geometry and critical access points defines the H135 Side Access Docking Platform as an indispensable asset for comprehensive, safe, and efficient Airbus H135 fleet maintenance.