Complete Access with the H125 Tail and Boom Combination Stand

Improve the safety and precision of your Airbus H125 maintenance operations with the specialized H125 Tail and Boom Combination Stand Access Platform. This engineered system provides unparalleled access to the most critical aft sections of the aircraft. Technicians can perform all necessary tasks, from routine inspections to detailed structural repairs, with maximum efficiency and security. This platform is a leading asset for maintaining the optimal readiness and airworthiness of your H125 fleet.

Comprehensive Coverage of Tail Boom and Rotor

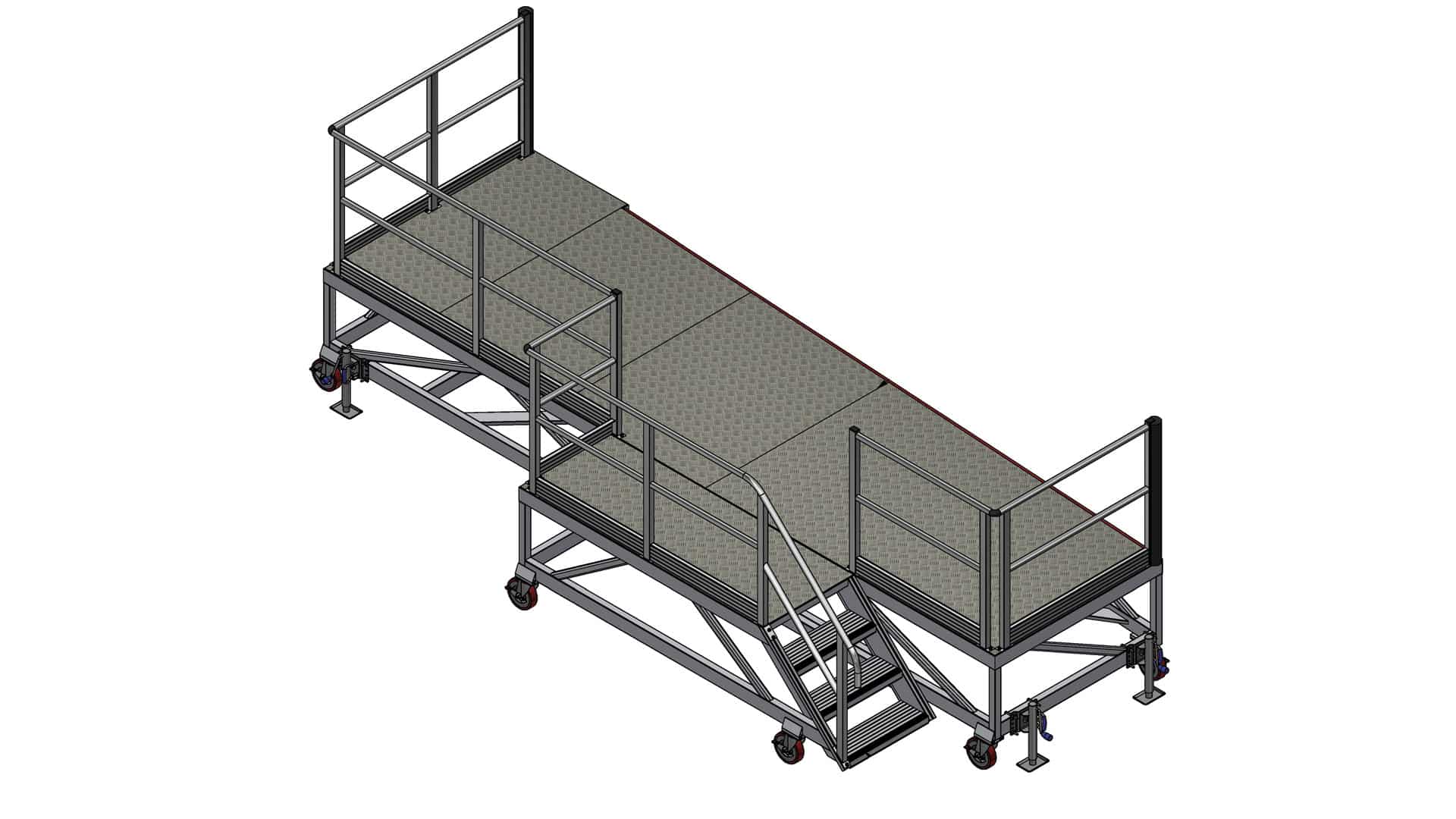

Designed explicitly for the unique contours of the Airbus H125 (formerly AS350 Écureuil), this platform set—comprising both Left-Hand (LH) and Right-Hand (RH) components—forms a comprehensive working envelope around the helicopter’s tail structure. Its primary function is to grant complete, stable, and ergonomic access to the tail boom, the crucial link between the fuselage and the tail rotor, and the delicate tail rotor assembly itself.

Efficiency with the H125 Tail and Boom Combination Stand

The working deck is constructed with high-grip treadplate decking, providing a secure, slip-resistant surface in any hangar environment. The generous surface area of the platform is a key feature, transforming cramped access into a spacious and stable zone for deeper levels of maintenance that require more tools, components, and personnel. This large working space ensures technicians are not restricted, allowing for faster fault diagnosis and component replacement without compromising safety or quality. This is how we keep people safe faster and companies productive for longer.

Advanced Safety Features

Safety is paramount, and every design element reinforces this commitment. The platform is fitted with protective foam on all leading edges, safeguarding the aircraft’s delicate skin and minimizing the risk of damage during abutment and use. Access to the main deck is provided via a secure 45-degree access stair, featuring grip-tread nosing for reliable ascent and descent, even when personnel are carrying tools and parts. This design eliminates the instability associated with conventional ladders or steps, promoting a safer working environment. We ensure people arrive home safe every day by designing systems that meet and exceed the world’s strictest safety standards.

Optimized Mobility and Setup

Mobility and adaptability are built into the core design. The platform is supported by sturdy 200mm swivel and braked castors, allowing for effortless positioning and relocation within the maintenance area. Once in position, wind-down adjustment jacks provide final stabilization, ensuring the platform remains rigidly fixed and level against the hangar floor throughout the maintenance procedure. This precision adjustment capability is foundational for aligning the platform precisely with the aircraft’s tail boom, a critical requirement for accurate work. The unique step-out configuration at the rear of the platform is a deliberate feature to accommodate the geometry of the H125, allowing for seamless abutment and integration with the corresponding Right-Hand (RH) platform. This combination creates a unified, gap-free work area that completely encompasses the maintenance area of the tail structure.

Core Maintenance Capabilities

Maintenance tasks facilitated by this H125 Tail and Boom Combination Stand platform include, but are not limited to, detailed visual inspections of the tail rotor blades and pitch change links, lubrication checks, servicing of the tail rotor gearbox, and crucial checks of the tail boom’s structural integrity, particularly around connection points and bulkheads. Furthermore, the stable access allows technicians to perform complex adjustments to control cables and linkages, ensuring the aircraft’s flight controls remain optimally tuned. For more intensive checks, such as those required during major service intervals, the platform allows for safe removal and reinstallation of components on the tail structure. By offering comprehensive access to the full length of the tail boom and its assemblies, this platform minimizes downtime and maximizes the safety and efficiency of all operations performed on the Airbus H125. View our specialized access solutions for other Airbus helicopters.