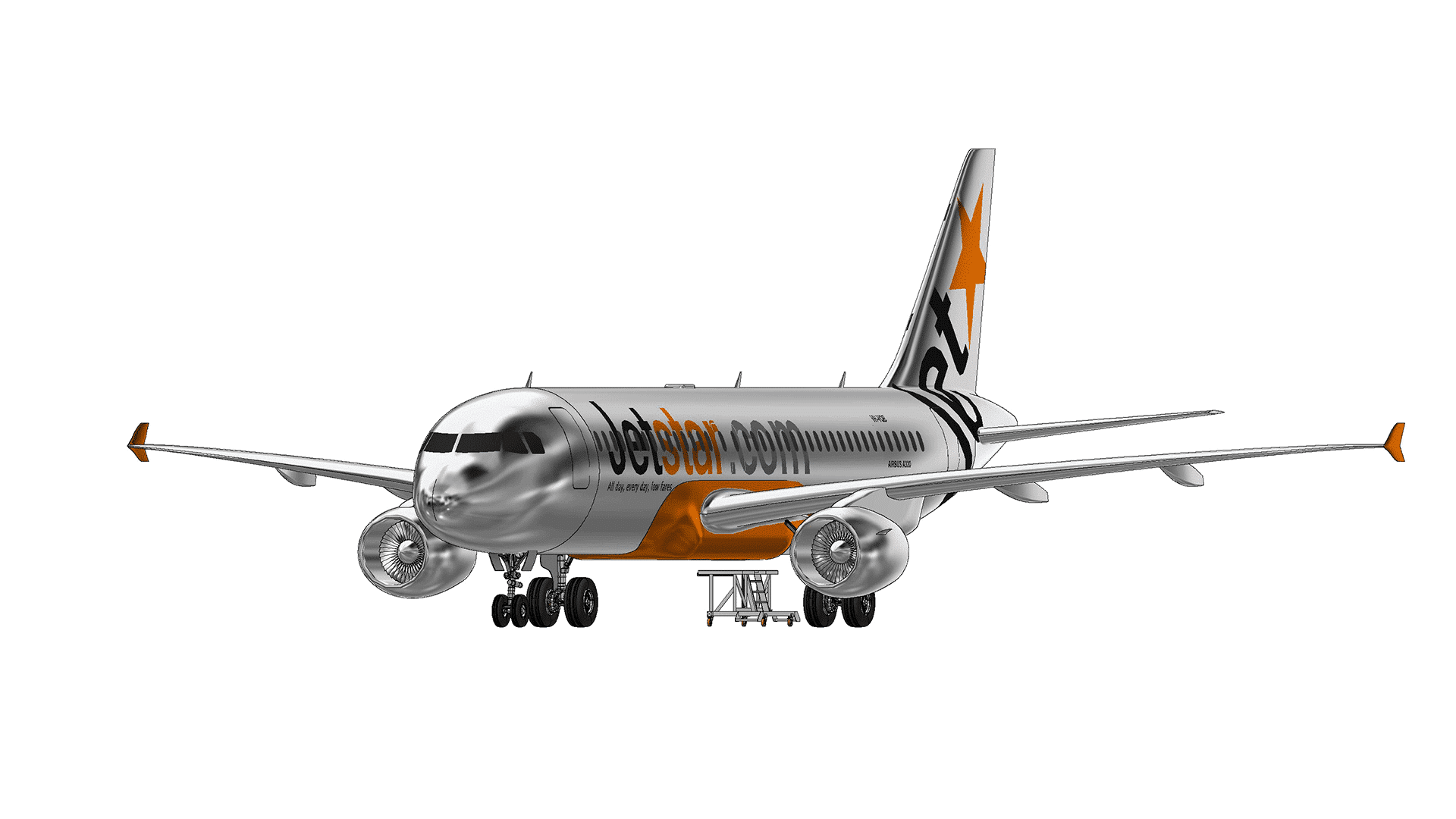

Optimized Access for the A320 MLG Area

This access solution elevates safety and efficiency for aircraft maintenance. It is specifically engineered as an A320 Main Landing Gear Split Level Platform for the Airbus A320 Main Landing Gear (MLG) area. The Split Level Platform is not a generic stand; it is a systematically designed system that addresses the unique requirements of accessing the main undercarriage for routine inspections, complex troubleshooting, and scheduled maintenance.

The MLG bay of the A320 is a critical area, containing structural elements, hydraulic lines, braking systems, electrical wiring, and the wheel assembly. Precise, stable, and comprehensive access is paramount here, as maintenance errors carry profound operational and safety consequences. This platform provides that foundational stability and reach, translating directly into enhanced safety for maintenance personnel and reduced turnaround time for the aircraft.

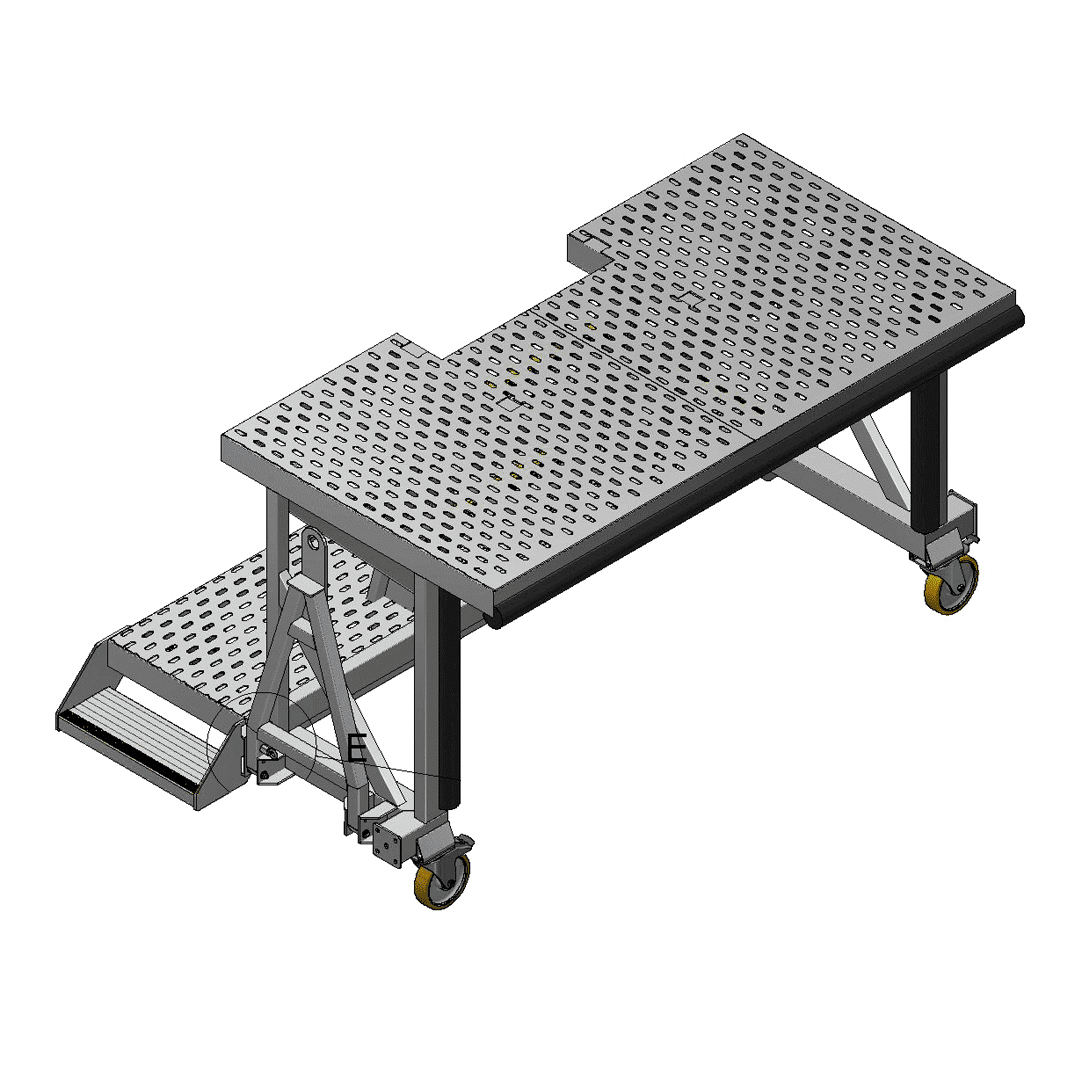

Dual-Level Design for Comprehensive Access

Innovative features include the intelligent split-level design. This design provides distinct, secure working heights tailored to the geometry of the A320’s MLG.

Wheel Strut Access and Brake System Checks

The lower platform component is ideally positioned, giving technicians full, unobstructed access to the wheel strut, brake assemblies, and tire pressure checks. This height eliminates the need for improvised access or leaning, ensuring all work on the wheel area, including removal and installation, is conducted from a secure, level footing. The upper platform, seamlessly integrated, offers the ideal height and proximity for thorough inspection and maintenance of the primary landing gear components.

These components include the main structure, uplock mechanisms, door sequencing systems, and various sensors and plumbing within the landing gear bay aperture. This dual-level capability ensures technicians transition smoothly between tasks without repositioning cumbersome equipment, maximizing workflow efficiency in a confined area.

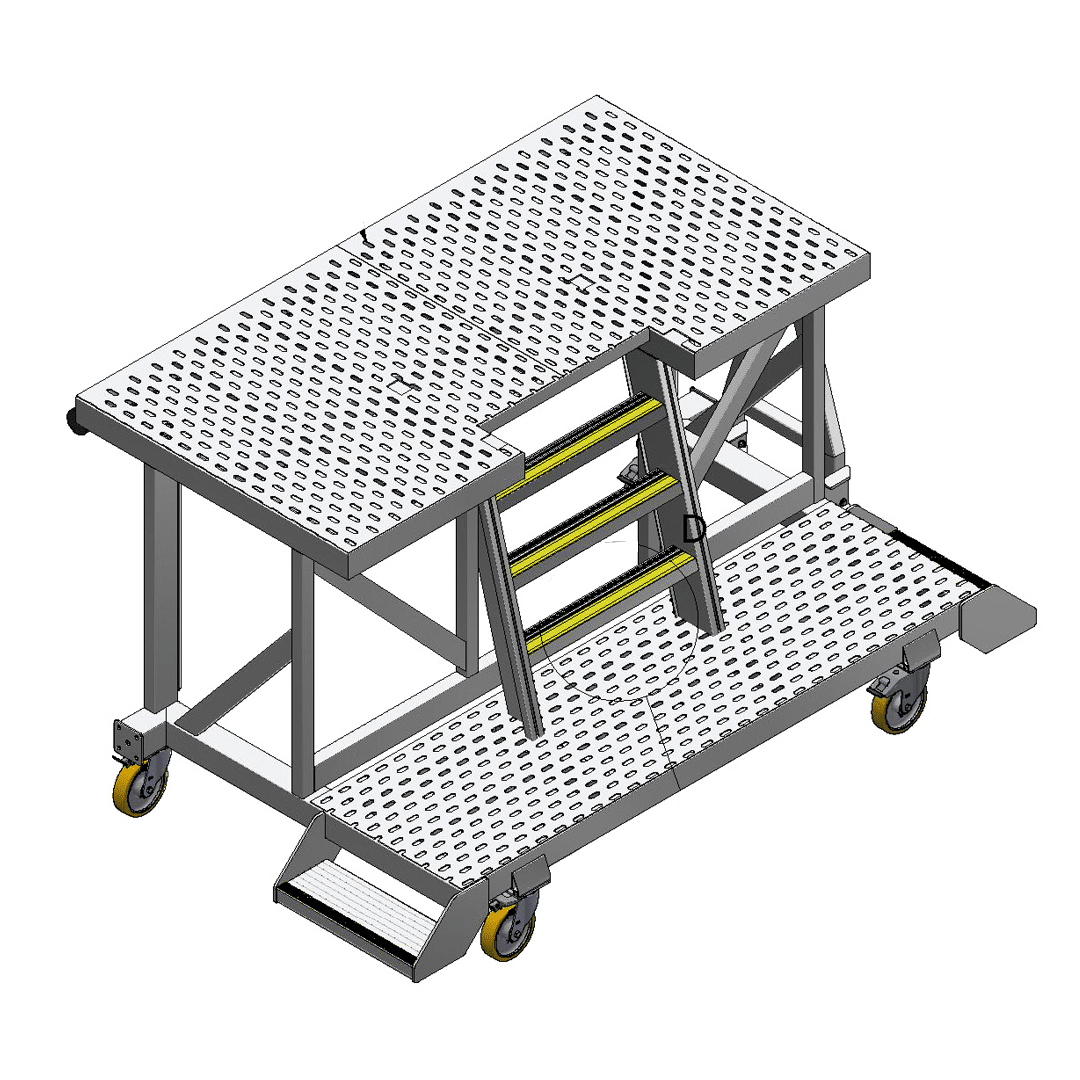

Enhanced Durability and Construction

Constructed from sturdy, high-tensile, marine-grade aluminum, the A320 Main Landing Gear Split Level Platform is inherently lightweight yet exceptionally durable. This material choice provides superior resistance to corrosion from hydraulic fluids, cleaning agents, and harsh hangar environments, guaranteeing a long service life and reliable performance.

The low overall weight is a key operational benefit, making it towable and easily maneuverable by a single technician around the line maintenance or hangar environment.

Safety Features and Compliance

Safety features are integrated at every point of use. The working deck features a perforated and swaged surface. This specialized decking ensures immediate and comprehensive drainage of oil, hydraulic fluid, water, and other moisture, preventing pooling and eliminating slip hazards—a crucial safety enhancement when working around lubricated mechanical assemblies.

Optional Telescopic Guardrails for Versatility

For added flexibility and comprehensive coverage across the aircraft’s surface, the A320 Main Landing Gear Split Level Platform is available with optional telescopic guardrails. When deployed, these guardrails extend to interface safely with adjacent airframe structures, making the platform adaptable for use in other high-access areas of the A320 family (such as wing leading edges or engine nacelles) where fall protection is necessary.

The standard guardrails provide a secure perimeter, adhering to the highest standards of safety regulation. You may also be interested in our dedicated access solutions for other areas of the aircraft, such as the windshield.

Minimizing Aircraft Downtime

The design centers on minimizing aircraft downtime. By providing secure, multi-level access that conforms perfectly to the contours of the A320’s main undercarriage, it reduces the complexity and time required for scheduled checks and unexpected repairs. Maintenance technicians rely on a firm, non-wobbling work surface, enabling them to focus entirely on the precision tasks required for airworthiness.

Sturdy locking mechanisms, paired with swivel casters, ensure the platform remains absolutely stationary once in position, providing maximum load-bearing stability for two technicians plus tools. This dedicated equipment is indispensable for any facility performing comprehensive base or line maintenance on the Airbus A320 family aircraft, serving as a pillar of safety and productivity in commercial aviation maintenance.