Lockheed Martin F-35 Lightning II

The world class F-35 fighter jet is an impressively advanced and capable multirole fighter being rolled out amongst the participating nations militaries in the Joint Strike Fighter program.

Because of its high performance and complex design, the inspection, maintenance, and repair schedules for this aircraft are crucial to its continued efficacy and capacity as a strike aircraft. Ground teams and their engineers and technicians require safe and efficient access to all aspects of the F-35 fighter.

But with many maintenance, repair, and overhaul tasks to be undertaken across the fighter’s advanced avionics, complex STOVL design and myriad of ordnance systems, ground teams need to not only protect themselves but also the aircraft’s various components.

One option is to create full surround platforms. Suitable in some scenarios, but more can create more problems in others. Fully elevated and guardrailed scaffolds can often be bulky to manoeuvre and restrict access to entire systems on the fighter. But what if an access solution could be smaller, easily manoeuvrable, and height adjustable without compromising safety?

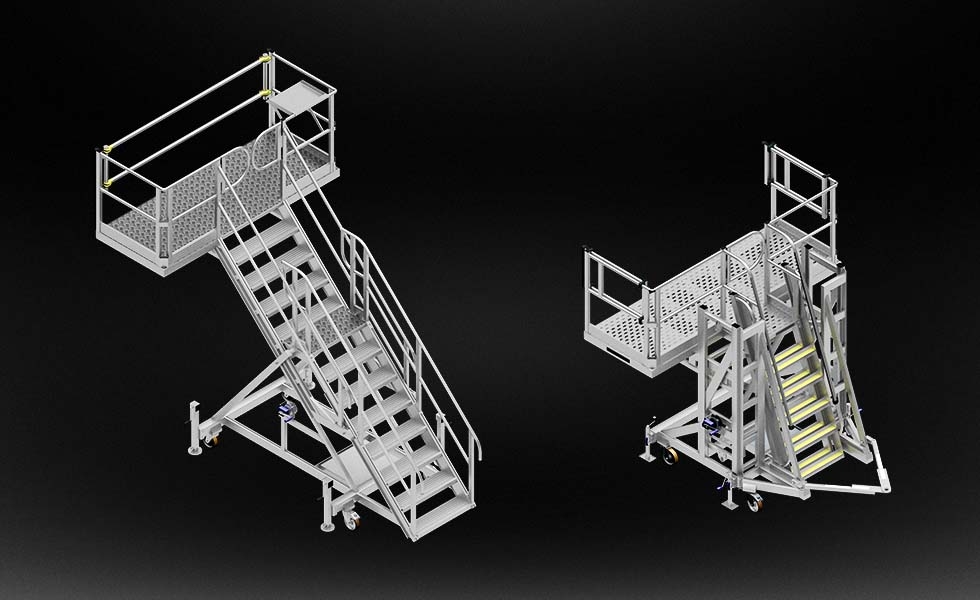

Two cantilivered platforms specifically developed for the F-35 JSF

Working with ground teams and maintenance personnel, SafeSmart Aviation's internal team of engineering and technical experts in the aviation industry created two outstanding options. The Multi-Purpose Cantilevered Stand overcomes working safely at heights on the aircraft while providing a better solution than full surround solutions. Available in either 45-degree access or 70 degree access, these platforms are 100% manually adjustable in height and protect both aircraft and maintenance personnel.

Completely manoeuvrable for easy repositioning with their castors & wind down jacks plus they're light with marine grade aluminium construction.

After consultation with ground teams, we learnt that egress via a comfortable angle and unrestricted movement on working areas were extremely important to their ability to execute tasks during MRO work. As a result, each platform has a large working area, adjustable with a manual winch to any height up to 2.8 metres for the 70-degree model and 2.6 metres for the 2.6 meter 45-degree model.

Both platforms are cantilevered out each side providing a larger work area while securing each platform is easy with the top mounted wind down jacks that level and stabilise the platform on any surface. Additionally, the 70-degree platform comes complete with towing capabilities for fast deployment in hangars.

Protecting the composite material of their airframe was imperative while works were being undertaken. To minimise the risk of damage to the fighter, strategic positioning of protective rubber foam line the leading edge on both platforms. With telescopic guardrails mounted on the 70-degree platform's working area providing extra protection, no matter it’s positioning.

Finally, MRO personnel are fully protected at the top of the work area. The 45-degree platform provides full surround protection with guardrails (top and mid) and spring-load batwing gate. Once positioned against the work area, the 70-degree platform secures personnel with the spring-loaded batwing gate plus telescopic guardrails for added protection.

Experts in Height Access Solutions

Working with industry leaders to overcome their height access challenges is what we do everyday. And the collaboration between our client on the F-35 maintenance platforms was no different.

We work directly with the engineers, ground teams, and maintenance personnel who will be performing their tasks with our platforms. This not only solves the problem for our clients, but it also gives them control over the platform they'll be using. Our clients feel safer at heights knowing that they've had a hand in creating a platform for themselves.

Reach out to us if you have any questions on our F-35 Multi-Purpose Cantilevered Stand or how we can help you overcome your height access challenges.