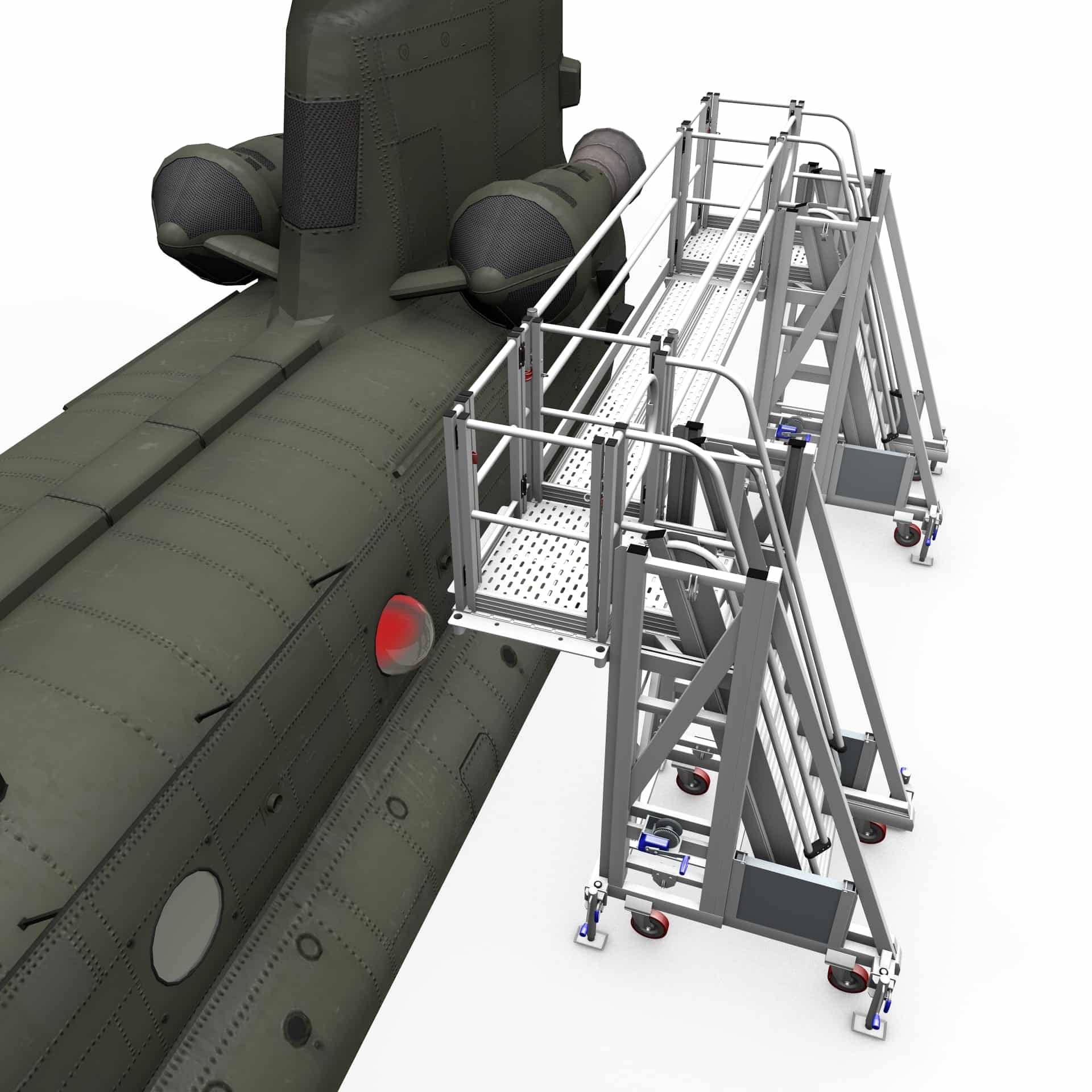

A Complete Solution for CH-47 Line Maintenance

The Boeing CH-47 Line Maintenance Platform Set is a compact, mobile and highly adjustable access system engineered for the varied height demands of CH-47 Chinook maintenance. With its wide adjustment range, strong cantilever reach and flexible multi-direction access paths, this platform set supports technicians working across the aircraft’s complex airframe—rotor systems, transmission decks, engine bays, flight controls, upper fuselage panels and cabin roof structures. The flexibility offered by the CH-47 Line Maintenance Platform Set is crucial for fast-paced hangar operations.

Precision Height and Cantilever Reach

The platform’s height-adjustable design is controlled via a manual winch, giving technicians precise, steady movement to the exact working level required. This range is particularly valuable on the CH-47, where maintenance zones vary dramatically—from low-side fuselage inspections to high, elevated work along the transmission bay and aft pylon. The platform maintains a clear 700mm cantilever at every height setting, allowing teams to reach over obstacles such as sponsons, gear housings or cabin structure without losing deck stability.

Flexible Multi-Directional Access

Three access directions off the main platform give crews the freedom to configure the unit for the specific task at hand. Whether technicians need forward, side or rear access to the aircraft, the platform can be positioned to match the workflow, reducing unnecessary repositioning. Innovative features include a loop guardrail attachment that can be placed in any of these directions, maintaining complete perimeter protection regardless of the setup. The guardrail support leg adjusts in 25mm increments, helping the system align accurately to the aircraft and stay stable at all working heights.

Modular Bridging for Continuous Workspaces

Bridging attachments allow multiple platforms to be joined together, creating larger, continuous work zones ideal for servicing rotor hubs, transmission components or upper fuselage panels. These bridging components are all under 17kg, making them simple to carry, position and install without specialised lifting equipment. The multiple configuration options mean crews can create straight runs, corners or wraparound access as needed for different maintenance stages. This modular approach supports detailed, multi-technician work while maintaining a clean, consistent safety boundary. For similar high-level precision access, consider our Boeing AH-64 Apache Maintenance Side Work Stands.

Enhanced Stability and Hangar Maneuverability

Large bubble levels at each jack point assist with accurate levelling, ensuring the platform sits solidly even on imperfect hangar floors. Once levelled, the stand remains firmly anchored, giving technicians a dependable footing when performing tasks such as:

- Engine checks and cowl access.

- Rotor-head and pitch-link inspections.

- Hydraulic and fuel system servicing.

- Flight-control linkage adjustments.

- Structural assessments across upper surfaces.

Because the platform is compact and easy to manoeuvre, it fits seamlessly into busy hangar layouts where multiple aircraft or support equipment may already be staged. Its mobility allows ground crews to shift between tasks quickly, supporting the fast-paced nature of Chinook maintenance programs—whether for line-level inspections, scheduled servicing, or component troubleshooting. The platform set’s adjustable guardrails, stable cantilever, light bridging elements and flexible directional access combine to create a multi-purpose system that adapts to the CH-47’s unique geometry. Technicians gain safe reach into areas that typically require multiple stand types, helping streamline operations and reduce equipment clutter around the aircraft. Hard-wearing, adaptable and purpose-focused, the Boeing CH-47 Line Maintenance Platform Set provides a clear, reliable solution for accessing the wide range of maintenance points on the Chinook. Its stability, adjustability and user-friendly setup keep crews safe, productive and ready to tackle work anywhere on the airframe.