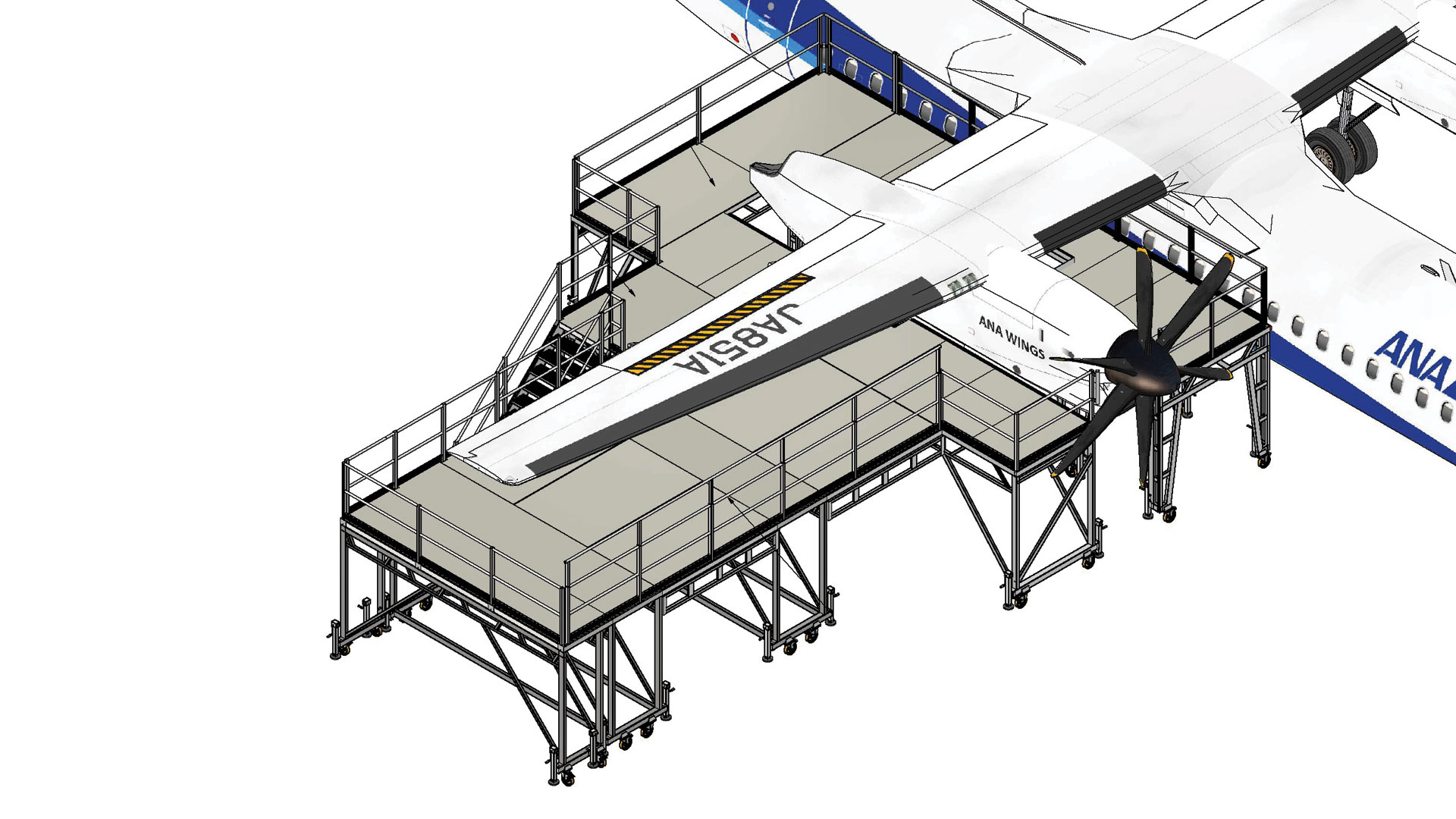

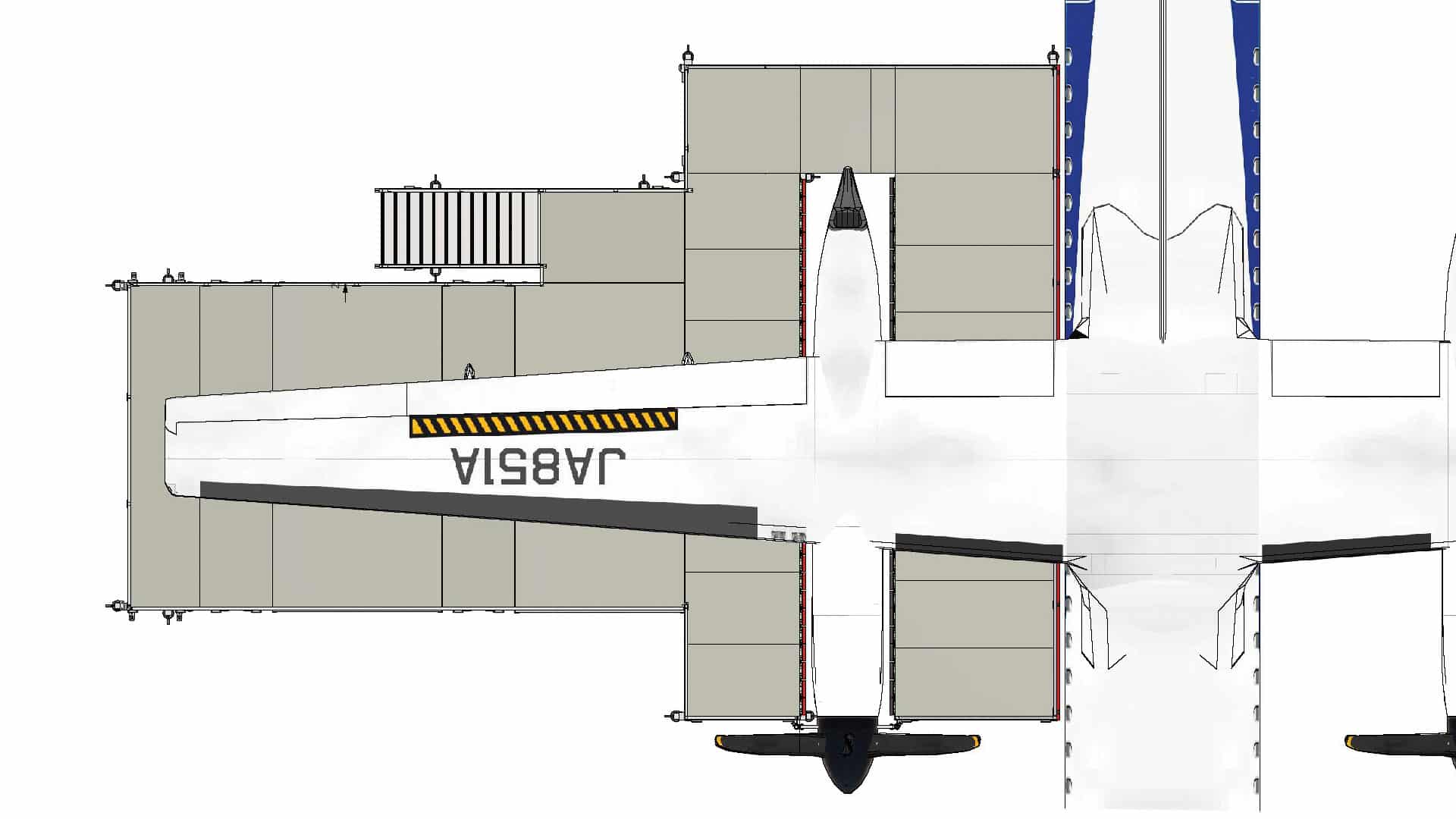

Bombardier Q300/Q400 Underwing Dock – Medium Version

The Bombardier Q300/Q400 Underwing Medium Dock delivers comprehensive access for maintaining this high-wing, T-tail regional airliner. Engineered specifically for the Q300 and Q400 airframes, this mobile aluminum wing and engine docking system provides seamless, broad access to critical areas. Its configuration is methodically planned to support maintenance requirements, with a focus on accessibility to the engines, propellers, landing gear, and the high wing structure.

The system’s core strength lies in its configurable modules and lightweight, yet sturdy, high-tensile marine-grade aluminum construction. This material choice ensures durability and longevity, resisting all-weather exposure and common aviation fluids. The inherent low weight also makes the dock highly manoeuvrable—an essential advantage in busy hangars where access platforms must be frequently repositioned. A towable design further simplifies relocation across the maintenance facility, supporting faster workflows and improved efficiency.

Modular Sections for Task-Specific Alignment

The platform sections are modular, enabling flexibility to align the dock precisely to the immediate maintenance task. Stepped platform sections are engineered to support both over-wing and under-wing access. This dual capability is particularly valuable on the Bombardier Q-series, including maintenance activities such as reaching fuel systems via over-wing fueling ports. In addition, the underwing focus of this dock version allows technicians to efficiently access the main landing gear housed within the nacelles and the underside of the high wing structure.

Optimized Engine and Propeller Access

Engine and propeller servicing is a primary consideration—especially for the Q400’s powerful 6-blade composite propellers. The dock provides close-proximity, stable working positions for propeller system tasks such as greasing, balancing, and de-ice servicing, as well as engine-related work including gearbox checks, oil level verification via the low-access dipstick in the nacelle, and chip detector monitoring. The configuration accommodates the Q400’s higher stance, delivering safe working heights around the propeller arc and supporting efficient access to the top of the engine nacelle where prop controls are located.

Safety Features and Efficient Maintenance Flow

Safety and operational efficiency are enhanced through integrated features designed for real-world maintenance environments. Removable guardrails allow technicians to isolate and secure individual platform sections, adapting the safety perimeter as needed while maintaining strong fall protection—even when parts of the platform are opened to the aircraft. Angled or stepped height options help align the working surface with the aircraft’s contours. Gated sections support safer transfer of tools, materials, and components between the platform and the work area, streamlining workflow and reducing handling risks.

Bridge Platforms, Stair Access, and Close-In Positioning

Innovative features include adjoining bridge platforms that can span gaps or interface with other access equipment, expanding coverage across complex maintenance zones. Stair access with landings provides comfortable, secure entry and exit points for personnel and tooling. Sliding handrails allow the platform to be positioned as close as possible to the aircraft surface while maintaining barrier integrity. Inboard platform sections incorporate configurable modules to enhance access flexibility when working on intricate wing areas close to the fuselage.

Comprehensive Coverage for Q300/Q400 Maintenance

By providing stable, height-appropriate access around the wing and engine areas, this docking system reduces the risks associated with working at height and improves turnaround for routine and complex checks. It is an indispensable tool for maintaining high-cycle components such as landing gear, brakes, and nacelle systems, while also supporting broader servicing needs including hydraulics, APU access, and related airframe inspection zones on the Bombardier Q300/Q400 fleet.

Check out the large version of this dock, the Bombardier Q300/Q400 Underwing Dock – Large Version.